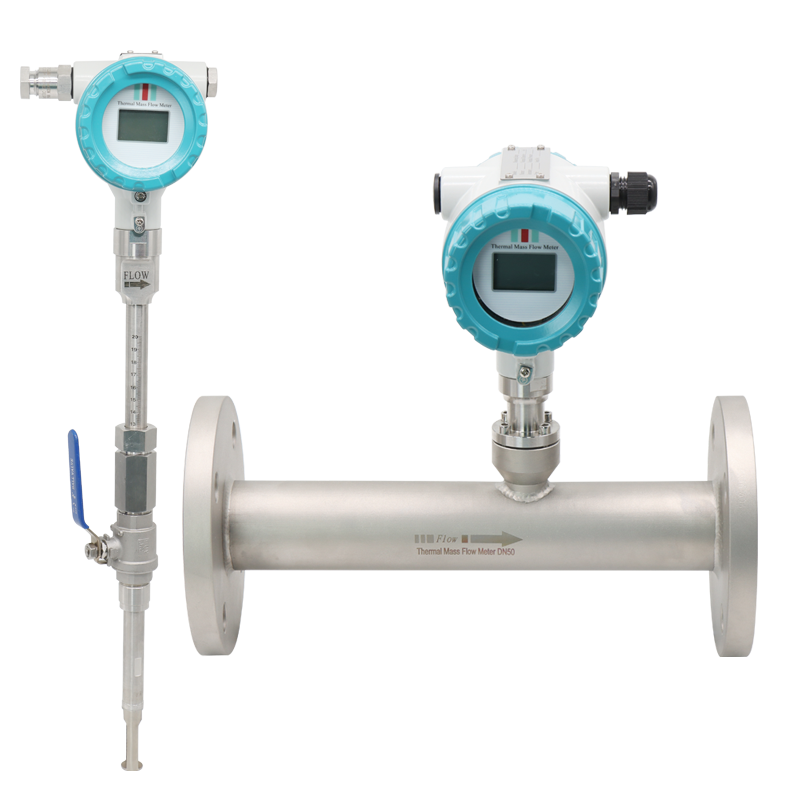

Air flow meters are essential devices used to measure the flow of air in various industrial and commercial applications. The accuracy and reliability of flow measurements depend significantly on the proper installation of the flow meter. To ensure optimal performance, careful attention must be given to the location and orientation of the meter within the system. Below, we discuss the critical factors that need to be considered when installing air flow meters, including installation location, direction, and other specific requirements for different applications.

1. Choosing the Installation Location

The placement of an air flow meter is crucial for accurate flow measurement. The meter should be installed in a straight section of the pipe to avoid turbulence that could distort readings. A few key considerations include:

Straight Pipe Section:

To ensure that the air flow entering the meter is laminar (uniform and stable), the flow meter should be installed in a straight section of pipe. Ideally, the length of the straight pipe before and after the meter should be at least 5 times the pipe diameter (5D). This minimizes the impact of pipe fittings such as bends, valves, and tees, which can cause flow disturbances.

Height of Installation:

The installation height varies depending on the size of the pipe and the type of meter. For pipes with a diameter of up to DN200, the installation height should be at least 0.5 meters; for larger pipes (greater than DN200), the height should be a minimum of 1 meter. Proper height ensures that there is enough space for the flow meter and that the measurement is not influenced by external factors such as vibrations or external obstructions.

Special Applications:

In some cases, particularly when measuring high-pressure or large-volume air flows, larger flow meters may be required. The installation position may need to be customized depending on the size of the flow meter and the nature of the application.

2. Proper Orientation of Air Flow Meters

The orientation of the air flow meter during installation is another important factor. Installing the meter in the correct orientation ensures that it functions correctly and provides accurate measurements. Here are the key guidelines:

Flow Direction:

Air flow meters are typically designed for unidirectional flow, meaning they measure flow in one direction only. It’s crucial to ensure that the direction of the air flow matches the flow direction indicated by the arrow on the meter. If the meter is installed in the reverse direction, it will either fail to provide correct readings or get damaged.

Vertical Pipe Installation:

When measuring air or gas flow in a vertical pipe, the flow direction does not have to be strictly controlled, but it’s important to consider the characteristics of the fluid. For instance, if the gas contains moisture, the flow should be directed upward to prevent liquid from entering the meter, which could interfere with the readings. If the gas flow is predominantly dry, vertical installations can be used flexibly.

Horizontal Pipe Installation:

In horizontal pipe installations, air flow meters should ideally be mounted on the side of the pipe. This ensures that the flow meter is not affected by temperature fluctuations, especially in the case of superheated steam or low-temperature liquids. Additionally, it is important not to install the meter at the highest point of the pipe, as this may cause air to accumulate, leading to inaccurate measurements.

3. Additional Installation Considerations

To achieve the highest level of accuracy, several other factors must be considered during the installation of air flow meters:

Straight Pipe Length Requirements:

As mentioned earlier, to prevent measurement errors caused by turbulence, it is essential to have sufficient straight pipe sections before and after the flow meter. Generally, the straight section before the meter should be at least 15 times the diameter of the pipe (15D), and after the meter, it should be at least 5 times the diameter (5D). The presence of elbows, reducers, or any other changes in pipe geometry can distort the flow pattern and affect the accuracy of the reading.

Pipe Diameter:

The pipe diameter should match the internal diameter of the flow meter to ensure proper flow through the meter. If the pipe is too large or too small compared to the meter’s diameter, it can lead to inaccurate measurements and possible flow disruptions.

Sealing:

When using sealing rings, make sure they are slightly larger than the internal diameter of the flow meter. Proper sealing ensures that there is no leakage of air and the measurements remain precise. Additionally, the sealing ring should be centered properly within the pipe to avoid leakage and ensure a secure installation.

4. Special Conditions for Installation

Certain conditions in the system may require specific considerations for the installation of air flow meters:

High-Temperature Fluids:

For measuring high-temperature gases, vertical installations are often recommended to prevent temperature-related damage to the flow meter. If horizontal installation is necessary, the flow meter’s transmitter should be positioned downward or on the side to minimize the effects of heat.

Pulsating Flows:

In cases where the air flow is pulsating, such as with compressors or blowers, installing the flow meter directly at the discharge point can lead to measurement errors. To mitigate this, a damping chamber or buffer tank can be used to smooth out the pulsations. Alternatively, placing the flow meter farther downstream, away from the pulsation source, can help to reduce errors.

Conclusion

The accurate measurement of air flow is critical in many industrial processes. Proper installation of the air flow meter is essential for ensuring the reliability and precision of the measurements. By following the guidelines for selecting an appropriate installation location, maintaining the correct orientation, and considering special factors such as high temperatures or pulsating flows, operators can ensure that their air flow meters provide accurate and consistent readings, improving overall system efficiency and performance.

If you want to know more about the flow meter or flow meter selection, please consult the Aister flow meter manufacturer email: sales@aistermeter.com for help.