Biogas flow meters are critical instruments used for measuring the flow of biogas, and their proper operation and maintenance are essential for the smooth functioning and production of biogas plants. Below is a detailed guide on the installation, daily operation, maintenance, and troubleshooting of biogas flow meters, aimed at extending the lifespan of the equipment and ensuring reliable performance.

1. Installation Guidelines

Instrument Inspection:

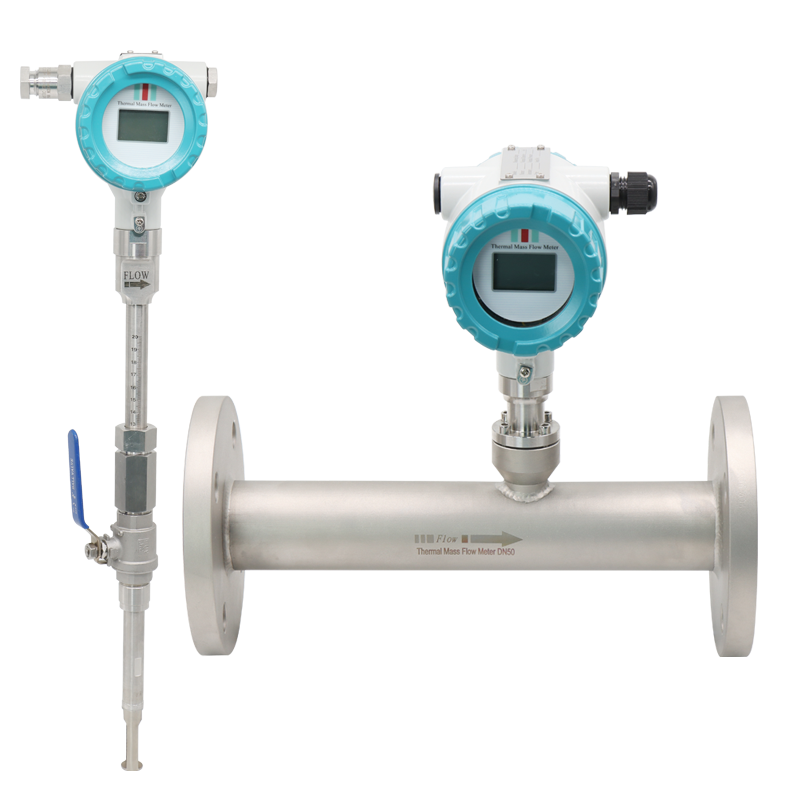

Before installation, inspect the biogas flow meter carefully to ensure it is free from cracks, leaks, or deformation. Also, verify that the meter comes equipped with the necessary valves and accessories.

Selecting Installation Location:

Choose a stable and well-ventilated location for the installation. The site should avoid direct exposure to sunlight and excessive moisture. Additionally, ensure the area is free from flammable, explosive, vibrating, corrosive, or radioactive environments that could harm the instrument.

Correct Pipe Connection:

Ensure that the flow meter is connected to the pipeline with the correct orientation and that the connection points align properly. Use standard pipe connection methods and avoid any impacts or abrasions that could damage the meter’s casing. After installation, perform a leak test to ensure the connections are tight and leak-free.

Electrical Connection:

Check that the positive and negative terminals are correctly wired, and ensure proper insulation and grounding of the instrument. This will guarantee both safety and ease of maintenance.

2. Daily Operation and Maintenance

Real-Time Monitoring and Adjustment:

While operating the biogas flow meter, adjust it according to production requirements and monitor the data in real time. It’s also important to regularly inspect the meter to quickly identify and resolve any issues, ensuring continuous operation of the biogas plant.

Routine Cleaning:

Regular cleaning is essential to remove any impurities or deposits inside the flow meter’s pipeline. This ensures accurate measurements. Be cautious not to damage any internal components of the flow meter during the cleaning process. Cleaning can be categorized into two types: routine cleaning (carried out daily or weekly) and necessary cleaning (performed during maintenance or repairs).

Instrument Calibration:

Regular calibration of the biogas flow meter is essential to detect and correct any measurement deviations. It is recommended to calibrate the instrument annually to maintain its accuracy. During calibration, follow the manufacturer’s instructions carefully to avoid over- or under-adjustment, which could affect the accuracy of measurements.

Minimizing Interference:

Ensure the flow meter is in an environment with minimal interference from external factors such as noise, vibration, or radiation. Additionally, ensure a stable power supply, proper grounding, and the use of appropriate protective measures to prevent damage from these factors.

Avoid Mechanical Damage:

During operation, avoid any physical impact or collision with the instrument. Only qualified maintenance personnel should handle repairs or maintenance, ensuring the correct procedures are followed and preventing further damage from improper handling.

3. Professional Maintenance and Troubleshooting

Professional Repairs:

For any repairs, always rely on qualified professionals. Unauthorized personnel should not attempt repairs, as improper handling may cause further damage.

Adhering to Operating Procedures:

During maintenance, use the appropriate tools and safety equipment to prevent injury or further issues. Pay close attention to the correct handling and disposal of chemicals to avoid accidental faults or damage to the equipment.

Routine Leak Testing:

Regularly inspect the connections between the flow meter and the pipeline to ensure they are properly sealed and free of leaks. Soap solution or a leak detector can be used to identify leaks. For instance, perform leak checks monthly to ensure no gas is escaping.

Check Tightening of Fasteners:

Inspect fasteners for any loosening. If necessary, tighten them immediately. For example, use a wrench to check that the bolts on flange connections are secure and properly tightened.

Monitor Display Screen:

Observe the flow meter’s display screen to ensure it is clear and showing accurate data. If the screen is blurry, flickering, or displaying errors, investigate the cause. For instance, check if the wiring is loose or if the screen surface is covered with dust that needs cleaning.

Inspect Indicator Lights:

Check whether the indicator lights are functioning correctly. Different colors may represent different operational statuses, such as normal operation or fault warnings. If the indicator lights are malfunctioning, follow the troubleshooting guidelines in the manual to resolve the issue.

By following this comprehensive maintenance guide, biogas flow meters will function efficiently and accurately, contributing to the optimal performance of biogas plants. Regular inspection, cleaning, and calibration, along with proper installation and professional repairs, will help extend the life of the equipment and ensure reliable operation.

If you want to know more about the flow meter or flow meter selection, please consult the Aister flow meter manufacturer email: sales@aistermeter.com for help.