The following is an overview of a thermal gas mass flowmeter manual:

Product overview

Thermal gas mass flowmeter is a flow measuring instrument based on the principle of thermal diffusion. It uses two sensors (temperature sensor and speed sensor) to measure the flow rate of the gas, and calculates the mass flow rate of the gas through the principle of constant temperature difference.

Working principle

When operating, a sensor continuously measures the temperature of the medium and acts as one side of the Wheatstone bridge (temperature sensor); The other sensor self-heats to a temperature above the medium and is used to sense the velocity of the flow body as the other side of the Wheatstone bridge (the velocity sensor). When there is a fluid flowing through, the gas molecules collide with the sensor and take away heat, causing the temperature of the speed sensor to drop. In order to maintain the constant temperature difference, it is necessary to increase the supply current of the speed sensor. The faster the gas flows, the more heat is taken away, and there is a fixed functional relationship between the increased heat and the gas flow rate.

Product characteristics

- High precision: can accurately measure the mass flow rate of gas, not affected by temperature and pressure.

- Wide range: Suitable for a wide range of flow rates, from very low to high flow rates can be measured.

- Wide range of applicable media: suitable for a variety of gas media, including dust, sand, moisture and various corrosive gases (except acetylene gas).

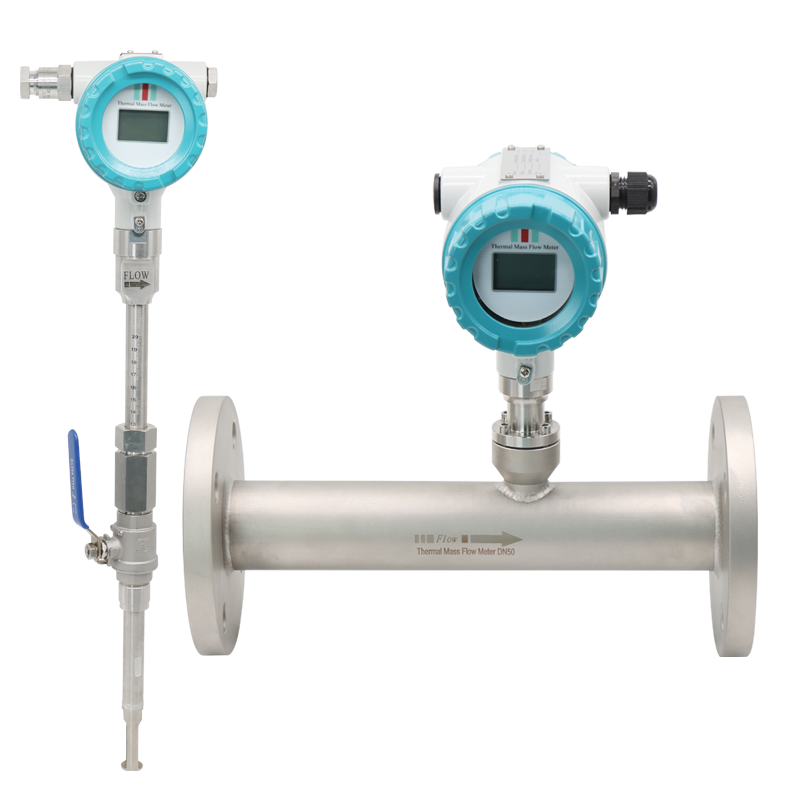

- Easy installation: Support plug-in and pipe type two installation methods, can be selected according to actual needs.

Technical specification

The technical specifications of the thermal gas mass flowmeter usually include accuracy, repeatability, upper and lower range, applicable pipe diameter range, applicable flow range, applicable pressure range, applicable medium temperature range and other parameters. Specific technical specifications may vary by model and brand.

Installation and maintenance

- Installation location: The installation should be carried out in a position where the fluid flow is stable and there is no vortex and vibration.

- Installation method: Install according to the selected installation method (insert type or flange type), follow the corresponding steps.

- Routine maintenance: Regularly check the cleanliness and working condition of the sensor, as well as the connection status of the cable. Do not perform online installation and maintenance operations when the medium temperature or pressure is too high.

Matters needing attention

Before use, please read the product manual carefully to understand the performance characteristics and use methods of the product.

When used in an explosive environment, explosion-proof instruments should be selected, and ensure that the explosion-proof temperature group of the instrument meets the requirements of the site.

Avoid use in temperature and pressure ranges that exceed the nominal value of the instrument.

If the product is suspected of failure, do not operate, should be checked and repaired by qualified maintenance personnel.

Application field

Thermal gas mass flowmeters are widely used in various occasions that need to measure gas flow, such as industrial process control, environmental monitoring, energy metering and other fields.

Please note that the above information is for reference only, and specific product characteristics and usage methods may vary according to different brands and models of thermal gas mass flowmeters. Be sure to refer to the instructions of the specific product before use.