Description

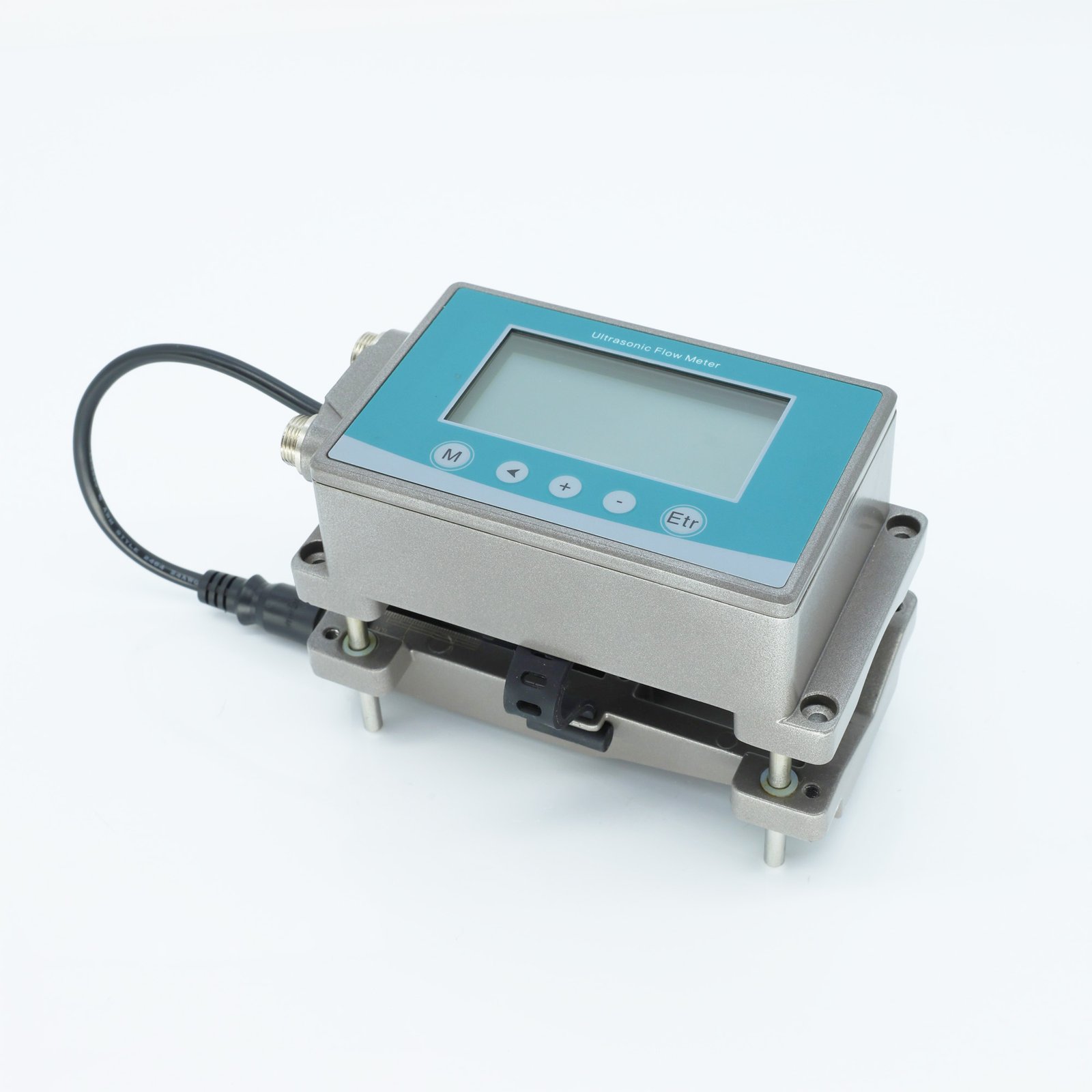

AT211 is an integrated type transfer time ultrasonic flow meter with the clamp on type transducers. It is compact and very easy to install, making it suitable for flow process monitoring application involving various small pipe size. It is also another good choice for the devices process equipment liquid monitoring.

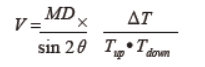

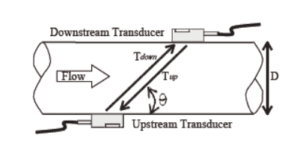

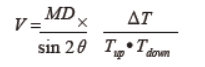

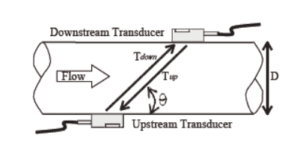

Working Principle

When the ultrasonic signal is transmitted through the flowing liquid, there will be a difference between the upstream and downstream transit time ( travel time or time of flight ), which is proportional to flow velocity, according to the formula below.

Remark:

V: Medium Velocity

M: Ultrasonic frequency of reflection

D: Pipe Diameter

θ: The angle between the ultrasonic signal and the flow

Tup: Transit time in the forward direction

Tdown: Transit time in the reverse direction

ΔT = Tup – Tdown

Specification

| Enclosure material |

PP and F |

| Mounting screw |

SS304 |

| Enclosure protection class |

IP54 |

| Vibration resistance |

10 to 55 Hz, double amplitude 1.5 mm, 2 hours in each XYZ axis |

| Impact resistant |

100 m/s2 16 ms pulse, 1000 times each for X, Y and Z axis |

| Models |

DN10、DN15、DN20、DN25、DN32、DN40 |

|

Flow range |

DN10 |

DN15 |

DN20 |

| 2 – 30 LPM |

5 – 60 LPM |

10 – 100 LPM |

| DN25 |

DN32 |

DN40 |

| 10 – 150 LPM |

20 – 260 LPM |

20 – 400 LPM |

|

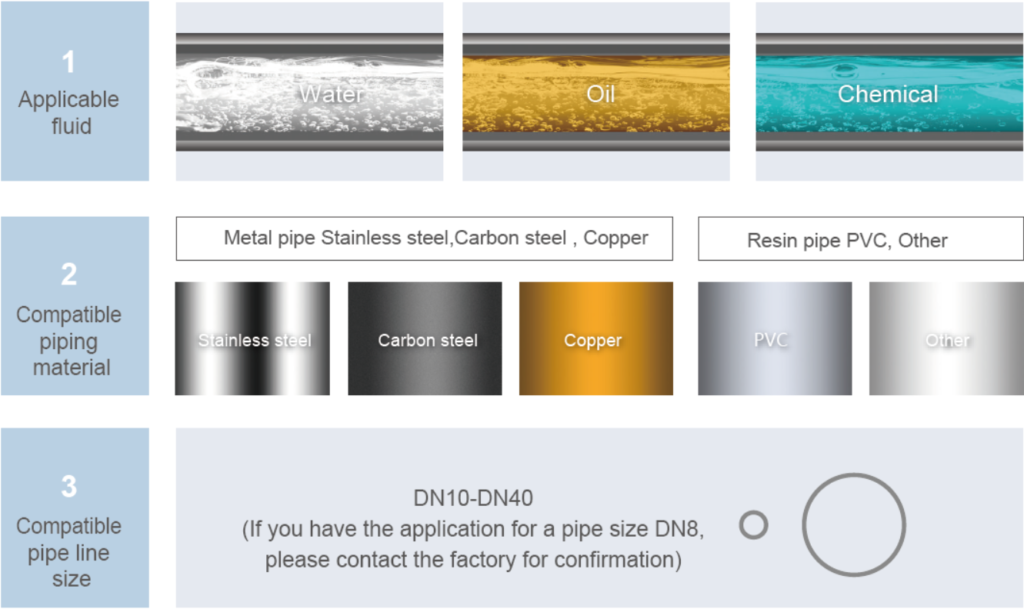

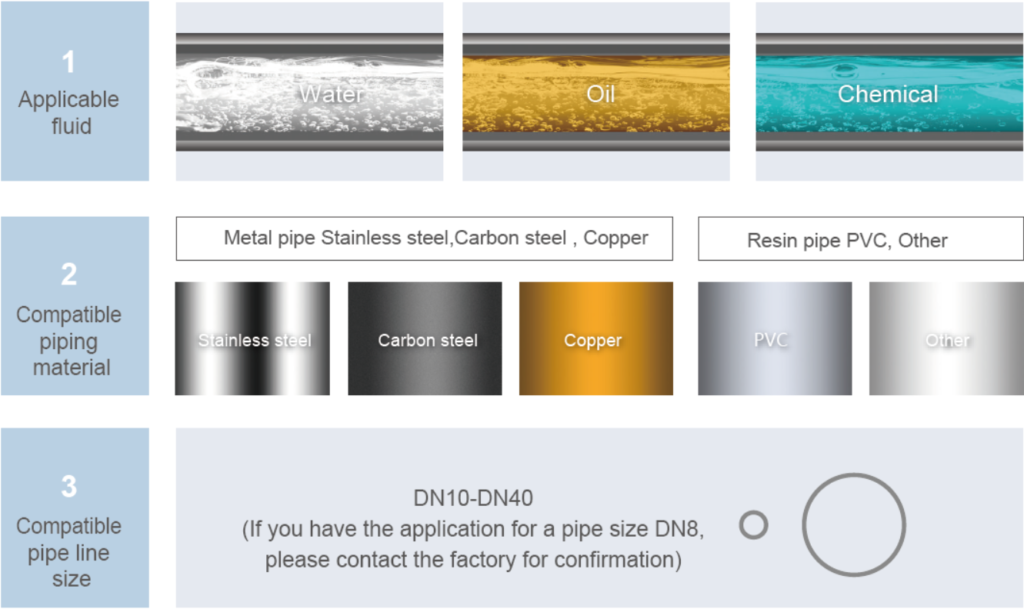

Pipe material |

Metal /PVC, PP, PE or PVDF rigid plastic pipe (Common examples, if not listed, please contact the factory for confirmation) |

|

Medium |

Water, Alcohol, Liquid gasoline, Chemical solvent and other fixed composition liquid other liquid (Single liquid medium without solid particles or impurities)

/Common examples, if not listed, please contact the factory for confirmation |

|

Medium temperature |

Standard :-10℃ – 65℃

Middle temperature transducers: -10℃ – 105℃ |

| Accuracy |

< 3% FS. |

| Response time |

0.5s – 3s |

| Power supply |

20-28VDC |

| Electric power |

1W |

| Power and I/O connection |

M12-A type aviation plug (Five-cores) |

| Output |

4-20mA |

| Communication |

RS485 Modbus |

| Display |

1.5′ OLed display |

| Keyboard |

2 touch buttons |

| Environment temperature |

-10℃ – 60℃ (No freezing) |

The outer diameter parameters supported by each specification are as follows

| Pipe size |

OD(mm) |

Flow range |

|

| DN8 |

Please contact the factory for confirmation |

| DN10 |

Ø12mm-Ø18mm |

2 – 30 LPM |

|

| DN15 |

Ø18mm-Ø23mm |

5 – 60 LPM |

|

| DN20 |

Ø23mm-Ø28mm |

10 – 100 LPM |

|

| DN25 |

Ø28mm-Ø33mm |

10 – 150 LPM |

|

| DN32 |

Ø33mm-Ø44mm |

20 – 260 LPM |

|

| DN40 |

Ø44mm-Ø52mm |

20 – 400 LPM |

|

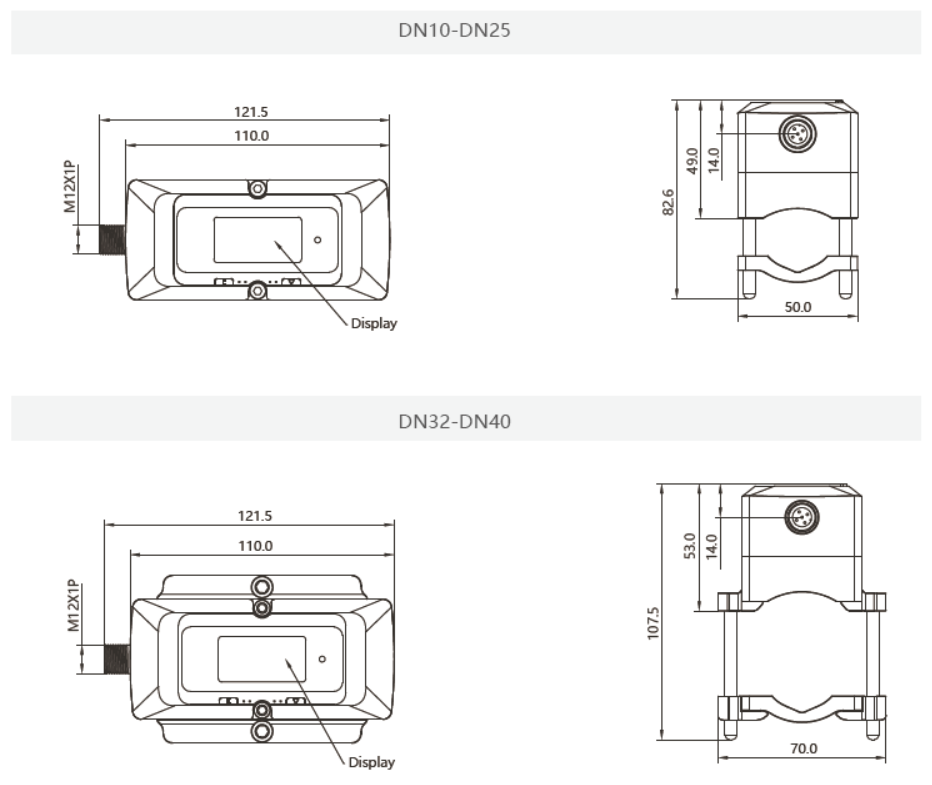

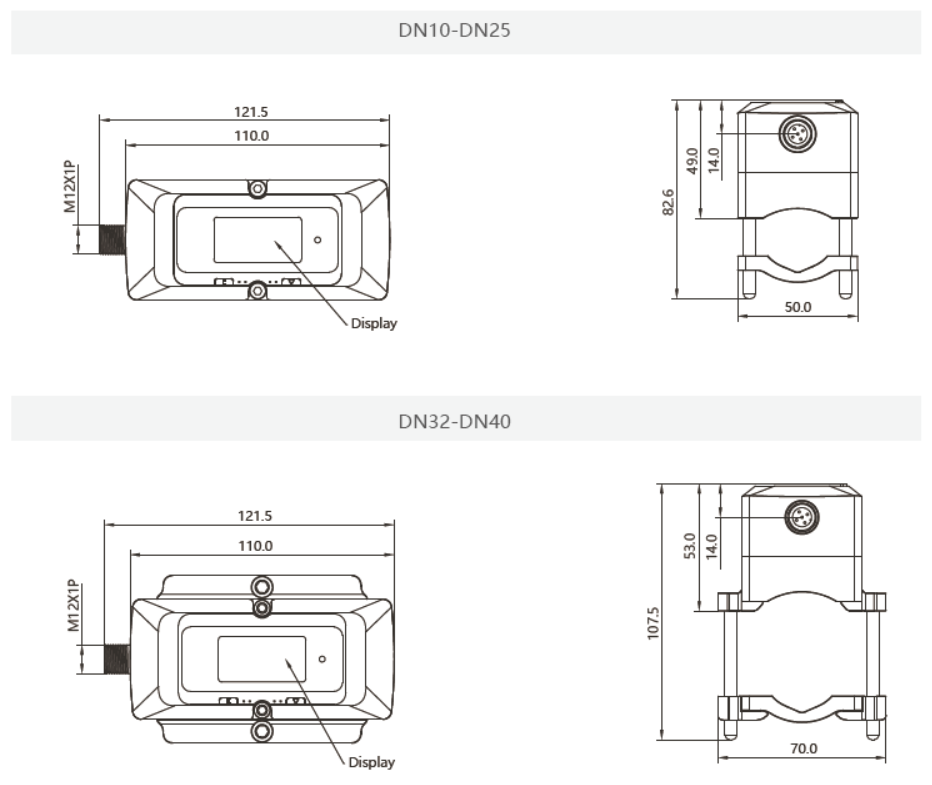

Size