Description

The Series Handheld Ultrasonic Flowmeter incorporates the latest ICs manufactured from the famous semiconductor manufacturers like Philips, Maxim, TI, Winbond, and Xilinx. The hardware features the ease of operation, high accuracy and outstanding reliability, while the software provides a user friendly interface and much more functions. It employs a patent balanced lower voltage multi-pulse igniting circuit which increases the anti-interference ability magnificently so that the flow meter will work properly even in demanding industrial environments such as those with power frequency transverter working nearby.

Other outstanding features:

—-the signal receiving circuits feature self-adapting performance so as to ensure that the user can easily operate the instrument without any adjustment.

—-the built-in rechargeable Ni-H battery can work continuously for more than 12 hours for a single charge.

The advanced circuit design, the integration of the latest semiconductors, the user-friendly software interface both in English and Chinese languages and small-sized PCB board, all these features combine to make the series ultrasonic flow meter the best and the biggest seller on the Chinese market. Moreover, it is gaining more and more recognition on the international flow meter market as well.

Working Principle

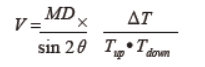

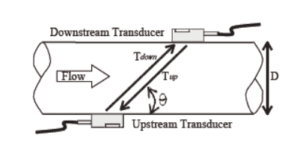

When the ultrasonic signal is transmitted through the flowing liquid, there will be a difference between the upstream and downstream transit time ( travel time or time of flight ), which is proportional to flow velocity, according to the formula below.

Remark:

V: Medium Velocity

M: Ultrasonic frequency of reflection

D: Pipe Diameter

θ: The angle between the ultrasonic signal and the flow

Tup: Transit time in the forward direction

Tdown: Transit time in the reverse direction

ΔT = Tup – Tdown