Electromagnetic flow meter is a speed instrument for measuring the volume flow of conductive medium. It outputs standard current signals for recording, adjustment and control while monitoring and displaying on the spot, so as to realize automatic control of detection and remote transmission of signals.

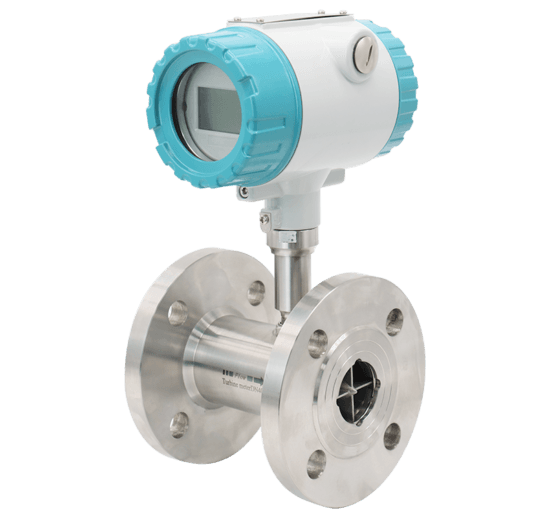

The electromagnetic flow meter comprises of interconnected transmitters and sensors that collaborate to accurately measure fluid flow. The sensor, designed with a direct connection, quantifies the induced voltage generated by the fluid as it traverses through the pipe. Subsequently, the transmitter gauges this voltage and converts it into a precise flow rate before transmitting the measurement data to the control system.

The flow principle behind electromagnetic flow meters is called Faraday’s Law, and its mathematical expression is defined as E=k*B*D*V. The induced voltage (E) is proportional to the speed (V) of the fluid passing through the magnetic field (B). The induced voltage enters the transmitter through the electrode loop. A transmitter then converts this voltage into a quantifiable flow speed. The volumetric flow rate of the fluid is calculated using this known velocity combined with the area of the pipe.

Electromagnetic flow meters are highly suitable for a diverse range of applications across various industries, including pulp and paper, metallurgy and mining, water and wastewater treatment, food and beverages, chemicals and petrochemicals, as well as oil and gas. Due to their streamlined design without any protrusions or obstructions in the pipeline, electromagnetic flow meters can be seamlessly adapted for an extensive array of applications encompassing clean liquids, slurring, as well as highly corrosive or abrasive fluids.