Partially-filed electromagnetic flow meter is composed of converter, flow sensor and level sensor. The user only needs to enter the diameter of pipe, the non-full pipe flow meter will automatically calculate the flow rate and automatically display the instantaneous flow, total flow, velocity, height, etc. it can measure liquid volume min 10% of full pipe. it is especially suitable for the needs of municipal rainwater, waste water, sewage discharge and irrigation.

The electromagnetic flow meter comprises of interconnected transmitters and sensors that collaborate to accurately measure fluid flow. The sensor, designed with a direct connection, quantifies the induced voltage generated by the fluid as it traverses through the pipe. Subsequently, the transmitter gauges this voltage and converts it into a precise flow rate before transmitting the measurement data to the control system.

The flow principle behind electromagnetic flow meters is called Faraday’s Law, and its mathematical expression is defined as E=k*B*D*V. The induced voltage (E) is proportional to the speed (V) of the fluid passing through the magnetic field (B). The induced voltage enters the transmitter through the electrode loop. A transmitter then converts this voltage into a quantifiable flow speed. The volumetric flow rate of the fluid is calculated using this known velocity combined with the area of the pipe.

Electromagnetic flow meters are highly suitable for a diverse range of applications across various industries, including pulp and paper, metallurgy and mining, water and wastewater treatment, food and beverages, chemicals and petrochemicals, as well as oil and gas. Due to their streamlined design without any protrusions or obstructions in the pipeline, electromagnetic flow meters can be seamlessly adapted for an extensive array of applications encompassing clean liquids, slurry, as well as highly corrosive or abrasive fluids.

Selection of Liner Materials for Electromagnetic Flow meters

The lining material should be selected according to the corrosiveness, abrasion and temperature of the measured medium.

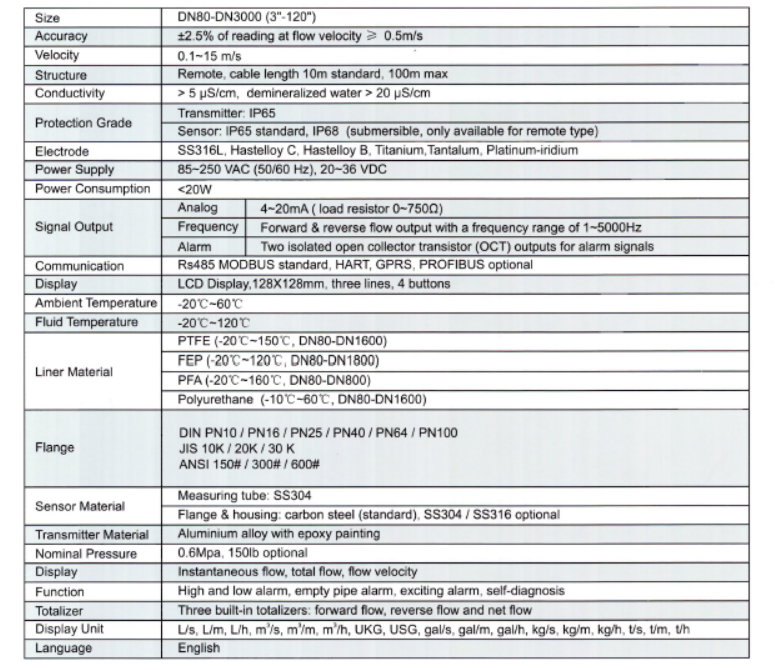

| Material | Main performance | Area of application | |

| Polyurethane rubber | 1. Good wear resistance

2. Poor acid and alkaline resistance |

<45℃

Measuring neutral strong wear of coal slurry, Mud and pulp |

|

| High temperature rubber | 1. It has good elasticity and wear resistance.

2. Resistant to general weak acids and weak bases. |

-70℃~+200℃

Measuring water and sewage |

|

| Acid-resistant rubber

(hard rubber) |

1. Resistant to the corrosion of hydrochloride acid, acetic acid, oxalic acid, ammonia water, phosphoric acid and 50% sulfuric acid and sodium hydroxide (potassium) at room temperature.

2. Not resistant to strong oxidant corrosion |

-25℃~+90℃

Determination of common acid, alkali and salt solutions |

|

| Chloroprene rubber | 1. Good elasticity and wear resistance

2. Resistant to the corrosion of ordinary low-concentration acid, alkali and salt solutions, but not resistant to the corrosion of oxidizing media. |

<80℃

Measuring water, sewage, mud and pulp |

|

| Fluorine

mould material |

PTFE

(F-4) |

1. Boiling-resistant hydrochloric acid, sulfuric acid, nitric acid, aqua regia, concentrated alkali and various organic solvents.

2. Strong wear resistance and poor adhesion. |

-40℃~+170℃

Strong corrosive solution of concentrated acid and concentrated alkali Liquid and sanitary medium |

| F-46

(FEP) |

1. Media that are not resistant to PTFE

2. Not resistant to fuming nitric acid and butyl lithium |

-40℃~+170℃

Can be use for higher negative pressure. |

|

| PFA | Chemical corrosion resistance is similar to FEP. | -40℃~+170℃

Same as FEP, can be used for higher negative pressure. |

|

Selection of Electrode Materials for Electromagnetic Flow meters

Corrosion resistance of electrode materials (for reference only)

| material | Corrosion resistance |

| Molybdenum stainless steel | Application: domestic/industrial water, sewage, weak acid-base salt solution, concentrated nitric acid at room temperature.

Not applicable: hydrofluoric acid, hydrochloric acid, chlorine, bromine, iodine and other media. |

| Hastelloy B | Application: A certain concentration of hydrochloric acid, hydrofluoric acid and other non-oxidizing acids and non-oxidizing hydrochloric acid, alkali solution such as sodium hydroxide with a concentration of not less than 70%.

Not applicable: oxidizing acids such as nitric acid. |

| Hartmann C | Application: Corrosion of oxidizing acid, such as mixed medium of nitric acid, mixed acid or sulfuric acid; It is also resistant to environmental corrosion caused by oxidizing salts or other oxidants. Such as hypochlorite solution higher than normal temperature; Very good corrosion resistance to seawater.

Not applicable: reducing acids and chlorides such as hydrochloric acid. |

| Titanium Ti | Application: chloride, hypochlorite, seawater, oxidizing acid.

Not applicable: reducing acids such as hydrochloric acid and sulfuric acid. |

| TanTalum Ta | Application: concentrated hydrochloric acid, nitric acid, sulfuric acid and most other acid solutions, including boiling hydrochloric acid, nitric acid and sulfuric acid below 175℃. Not applicable: alkali, hydrofluoric acid, fuming sulfuric acid |

| Platinum-Iridium alloy | All kinds of acids, bases and salts, excluding aqua regia. |