Introduction

The ultrasonic level meter, designed for measuring material and liquid levels, is a non-contact instrument renowned for its exceptional reliability, cost-effectiveness, and effortless installation and maintenance. This cutting-edge device fulfills the majority of level measurement requirements without direct contact with the medium, representing a new generation of proprietary technology developed by our company after years of dedicated research.

Applications

To ensure that the ultrasonic transmission to the measured liquid or material surface occasion, such as, storage tank, chute, pool, Wells, drains, metering box, granary etc.

Range

The instrument has the following range specifications:

Liquid level: 4m, 6m, 8m, 12m, 20m, 30m;

Material level: 3m, 5m, 7m, 10m, 15m;

The Blanking distance

| 4m | 6m | 8m | 12m | 20m | 30m |

| 0.20m | 0.25m | 0.30m | 0.50m | 0.80m | 1.2m |

Principle

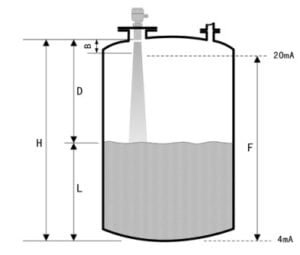

The sensor of the meter pulses in the direction of the product surface. There, they are reflected back and received by the sensor. The meter measures the time t between pulse transmission and reception. The meter uses the time t (and the velocity of sound) to calculate the distance D between the sensor membrane and the product surface:

D = c •t/2. As the device knows the empty distance H from a user entry, it can calculate the level as follows: L= H – D.

B: Blanking distance D: distance value L: level value

H: installation height F: level span

The ultrasonic velocity in gas is influenced by the gas temperature, So the level meter needs to detect the gas temperature at work. So, the material level meter needs to detect the gas temperature at work, compensation for sound velocity.

Blanking distance: Span F may not extend into the blanking distance B. Level echo from the blanking distance cannot be evaluated due to the transient characteristics of the sensor.