Introduction to Compressed Air Flow Measurement

Compressed air systems represent one of the most widely used industrial utilities, powering everything from pneumatic tools to automated production lines. However, compressed air is also one of the most expensive utilities to generate, with energy costs accounting for approximately 70-80% of the total cost of ownership over a compressed air system’s lifecycle.

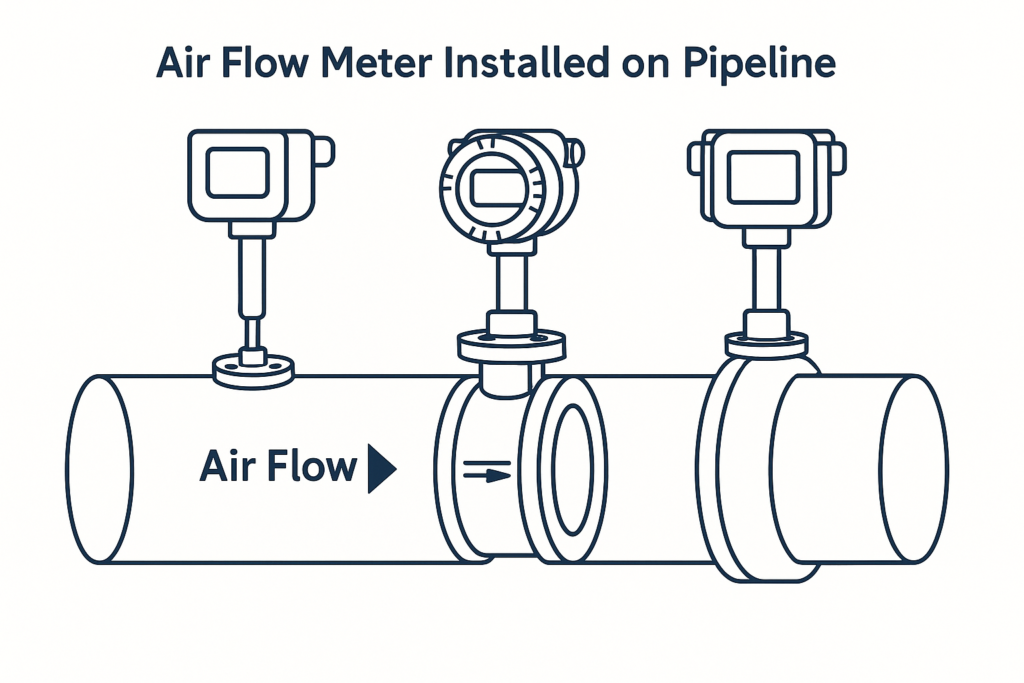

Accurate measurement and monitoring of compressed air flow rates have become critical for industrial facilities seeking to optimize energy efficiency, reduce operational costs, and maintain system reliability. A compressed air flow meter serves as the cornerstone technology for achieving these objectives, providing real-time data on consumption patterns, system performance, and potential inefficiencies.

The global compressed air flow meter market has experienced steady growth, driven by increasing industrial automation, stringent energy efficiency regulations, and growing awareness of compressed air system optimization. Modern facilities are implementing comprehensive compressed air monitoring systems that incorporate advanced flow meter technologies to achieve substantial energy savings and operational improvements.

What is a Compressed Air Flow Meter?

A compressed air flow meter is a specialized instrument designed to measure the volumetric or mass flow rate of compressed air within pneumatic systems. Unlike standard gas flow meters, these devices are specifically engineered to handle the unique characteristics of compressed air, including varying pressure levels, temperature fluctuations, and the presence of moisture and contaminants.

Definition and Purpose

Compressed air flow meters quantify the amount of compressed air flowing through a pipeline or system over a specific time period. The measurements are typically expressed in standard cubic feet per minute (SCFM), actual cubic feet per minute (ACFM), or cubic meters per hour (m³/h), depending on regional preferences and application requirements.

The primary purposes of compressed air flow measurement include:

- Energy management: Identifying high-consumption areas and optimization opportunities

- Leak detection: Monitoring baseline consumption to detect system leaks

- Cost allocation: Accurately billing different departments or processes for compressed air usage

- System sizing: Ensuring compressor capacity matches actual demand

- Performance monitoring: Tracking system efficiency over time

Key Characteristics

Modern compressed air flow meters are distinguished by several key characteristics that differentiate them from general-purpose gas flow meters:

Pressure Compensation: Most compressed air applications involve varying pressure conditions, requiring meters with built-in pressure compensation to provide accurate standard flow readings regardless of operating pressure fluctuations.

Temperature Correction: Compressed air systems generate heat during compression, and temperature variations can significantly affect flow readings. Advanced meters incorporate temperature sensors and correction algorithms to maintain accuracy across different operating temperatures.

Moisture Handling: Compressed air systems often contain moisture that can affect measurement accuracy and damage sensitive components. Specialized meters include features to handle condensation and maintain performance in humid conditions.

How Compressed Air Flow Meters Work

Understanding the operating principles of compressed air flow meters is essential for proper selection, installation, and operation. Different meter technologies employ various physical phenomena to detect and quantify flow rates.

Measurement Principles

Differential Pressure Measurement: This traditional approach measures the pressure difference across a flow restriction element such as an orifice plate, venturi tube, or flow nozzle. The pressure differential correlates directly with flow rate according to Bernoulli’s equation:

Q = K × √(ΔP × ρ)

Where:

- Q = Flow rate

- K = Discharge coefficient

- ΔP = Pressure differential

- ρ = Fluid density

Thermal Dispersion Technology: Thermal mass flow meters utilize the heat transfer properties of compressed air to determine mass flow rates. A heated sensor element is exposed to the flowing air stream, and the rate of heat dissipation is proportional to the mass flow rate.

Ultrasonic Transit Time: Ultrasonic meters measure the time difference for ultrasonic pulses traveling upstream and downstream across the pipe. The transit time differential is directly proportional to the flow velocity.

Signal Processing and Output

Modern compressed air flow meters incorporate sophisticated signal processing capabilities to enhance accuracy and provide versatile output options. Digital signal processors (DSP) analyze raw sensor data, apply compensation algorithms, and generate standardized output signals.

[Image: Cross-sectional diagram of a thermal mass flow meter showing sensor elements and flow path]

Common output formats include:

- 4-20 mA analog signals

- Digital pulse outputs

- Modbus RTU/TCP communication

- Ethernet connectivity

- Wireless transmission protocols

Compensation and Correction Algorithms

Advanced compressed air flow meters employ multiple compensation techniques to maintain accuracy across varying operating conditions:

Pressure Compensation: Real-time pressure measurements are used to convert actual flow rates to standard conditions, typically 14.7 PSIA and 70°F.

Temperature Compensation: Integrated temperature sensors provide data for thermal expansion corrections and density calculations.

Humidity Correction: Some high-precision meters incorporate humidity sensors to account for moisture content variations in the compressed air stream.

Types and Classifications of Compressed Air Flow Meters

The selection of appropriate compressed air flow meter technology depends on various factors including accuracy requirements, pressure conditions, pipe size, and budget constraints. Understanding the different types and their characteristics is crucial for making informed decisions.

Thermal Mass Flow Meters

Thermal mass flow meters represent the most popular choice for compressed air measurement applications due to their direct mass flow measurement capability and excellent accuracy across wide flow ranges.

Key features of thermal mass flow meters include:

- Direct mass flow measurement eliminates density calculations

- Wide turndown ratios (typically 100:1 or higher)

- No moving parts, resulting in minimal maintenance requirements

- Excellent low-flow sensitivity

- Built-in temperature and pressure compensation

Applications well-suited for thermal mass flow meters:

- Compressed air system monitoring

- Leak detection programs

- Individual equipment monitoring

- Energy management systems

[Table: Thermal Mass Flow Meter Specifications]

| Parameter | Typical Range | Accuracy |

|---|---|---|

| Flow Range | 0.1-1000 SFPS | ±1-2% of reading |

| Pressure Range | 0-500 PSIG | ±0.25% FS |

| Temperature Range | -40°F to +300°F | ±2°F |

| Turndown Ratio | 100:1 | N/A |

| Response Time | 1-3 seconds | N/A |

Vortex Flow Meters

Vortex flow meters operate on the principle of vortex shedding, where a bluff body placed in the flow stream creates alternating vortices downstream. The frequency of vortex shedding is proportional to the flow velocity.

Advantages of vortex meters for compressed air applications:

- Wide operating range with good accuracy

- No moving parts to wear or maintain

- Relatively low cost compared to other technologies

- Suitable for high-pressure applications

- Digital output proportional to flow rate

Limitations to consider:

- Minimum flow velocity requirements for reliable operation

- Sensitivity to upstream flow disturbances

- Potential issues with very low-density gases

- Vibration sensitivity in some installations

Ultrasonic Flow Meters

Ultrasonic flow meters offer non-intrusive measurement capabilities, making them attractive for retrofit applications where pipe cutting is not feasible. These meters can be classified into clamp-on and insertion types.

Benefits of ultrasonic technology:

- Non-intrusive installation options available

- No pressure loss across the meter

- Wide pipe size range capability

- Bi-directional flow measurement

- Self-diagnostic capabilities

Considerations for compressed air applications:

- Acoustic coupling requirements for clamp-on meters

- Pipe material and condition limitations

- Potential accuracy limitations at low flow rates

- Higher initial cost compared to some alternatives

Differential Pressure Meters

Traditional differential pressure meters continue to serve in many compressed air applications, particularly where cost is a primary consideration or where other technologies face limitations.

[Image: Cutaway view of an orifice plate differential pressure meter installation]

Common differential pressure elements include:

- Orifice plates

- Venturi tubes

- Flow nozzles

- Pitot tubes

Advantages of differential pressure meters:

- Well-established technology with extensive historical data

- Lower initial cost for basic installations

- Wide range of available sizes and configurations

- Suitable for high-pressure applications

- Accepted by most industry standards

Key Features and Components

Modern compressed air flow meters incorporate numerous advanced features and components designed to enhance performance, reliability, and ease of use. Understanding these elements is essential for proper specification and operation.

Sensor Technology

Primary Sensing Elements: The heart of any flow meter is its primary sensing element, which directly interacts with the flowing compressed air to generate a measurable signal. Different technologies employ various sensing principles:

- Thermal sensors: Precision resistance temperature detectors (RTDs) or thermistors for thermal mass flow meters

- Piezoelectric sensors: High-frequency crystals for ultrasonic meters

- Pressure sensors: Differential pressure transducers with silicon diaphragms

- Optical sensors: Laser-based systems for advanced particle detection

Secondary Sensors: Modern meters incorporate multiple secondary sensors to provide compensation and diagnostic information:

- Temperature sensors for thermal compensation

- Pressure sensors for density correction

- Humidity sensors for moisture content monitoring

- Vibration sensors for mechanical diagnostic purposes

Electronics and Signal Processing

Microprocessor Control: Contemporary compressed air flow meters utilize powerful microprocessors to perform complex calculations, implement compensation algorithms, and provide advanced diagnostic capabilities. These processors typically include:

- High-resolution analog-to-digital converters (ADC)

- Digital signal processing capabilities

- Non-volatile memory for configuration storage

- Real-time clock functions for data logging

- Communication interface controllers

Display and Interface: User-friendly interfaces are crucial for effective meter operation and maintenance. Modern meters typically feature:

- LCD or LED displays with multiple parameter views

- Intuitive menu navigation systems

- Local configuration capabilities

- Diagnostic status indicators

- Password protection for critical settings

Communication Capabilities

Standard Communication Protocols: Industrial compressed air flow meters support various communication standards to facilitate integration with control and monitoring systems:

- Modbus RTU: Serial communication for traditional PLC connections

- Modbus TCP: Ethernet-based communication for modern networks

- HART: Highway Addressable Remote Transducer protocol for analog systems

- Profibus: Fieldbus communication for Siemens-based systems

- DeviceNet: CAN-based network for Allen-Bradley systems

Wireless Options: Emerging wireless technologies offer installation flexibility and cost savings:

- Wi-Fi: Standard 802.11 protocols for existing wireless networks

- Bluetooth: Short-range communication for mobile device connectivity

- LoRaWAN: Long-range, low-power communication for distributed systems

- Cellular: 4G/5G connectivity for remote monitoring applications

Mechanical Construction

Housing Materials: Compressed air flow meters must withstand industrial environments while maintaining measurement accuracy. Common housing materials include:

- Aluminum: Lightweight and corrosion-resistant for general applications

- Stainless steel: Superior corrosion resistance for harsh environments

- Cast iron: Cost-effective for non-corrosive applications

- Exotic alloys: Specialized materials for extreme conditions

Ingress Protection: Environmental sealing is critical for reliable operation in industrial settings. Standard IP ratings for compressed air flow meters include:

- IP65: Protection against dust ingress and water jets

- IP67: Protection against temporary immersion

- IP68: Protection against continuous submersion

Technical Specifications and Performance Parameters

Understanding the technical specifications and performance parameters of compressed air flow meters is crucial for proper selection and application. These specifications determine the meter’s suitability for specific operating conditions and accuracy requirements.

Accuracy and Repeatability

Measurement Accuracy: The accuracy of compressed air flow meters varies significantly depending on the technology employed and the specific operating conditions. Accuracy is typically expressed as a percentage of reading or percentage of full scale.

[Table: Accuracy Comparison by Meter Type]

| Meter Type | Accuracy (% of Reading) | Repeatability | Turndown Ratio |

|---|---|---|---|

| Thermal Mass | ±1.0% to ±2.0% | ±0.2% | 100:1 |

| Vortex | ±1.0% to ±1.5% | ±0.1% | 20:1 |

| Ultrasonic | ±1.0% to ±2.0% | ±0.2% | 40:1 |

| Differential Pressure | ±1.0% to ±2.5% | ±0.1% | 4:1 |

| Coriolis | ±0.5% to ±1.0% | ±0.05% | 40:1 |

Factors Affecting Accuracy: Several factors can impact the measurement accuracy of compressed air flow meters:

- Flow Profile: Turbulence and swirl in the flow stream can affect accuracy, requiring adequate straight pipe runs upstream and downstream of the meter

- Temperature Variations: Rapid temperature changes can affect sensor performance and measurement stability

- Pressure Fluctuations: Dynamic pressure variations may impact accuracy, particularly for volumetric measurement technologies

- Contamination: Oil, moisture, and particulates in the compressed air can affect sensor performance over time

Operating Range Specifications

Pressure Range: Compressed air flow meters must be designed to handle the full range of system pressures encountered in typical applications. Standard pressure ranges include:

- Low Pressure: 0-50 PSIG for pneumatic tool applications

- Medium Pressure: 50-200 PSIG for general industrial applications

- High Pressure: 200-500 PSIG for specialized processes

- Extra High Pressure: 500+ PSIG for critical applications

Temperature Range: Operating temperature ranges must accommodate both ambient conditions and the heat generated by air compression:

- Standard Range: -20°F to +200°F (-29°C to +93°C)

- Extended Range: -40°F to +300°F (-40°C to +149°C)

- High Temperature: +300°F to +500°F (+149°C to +260°C)

Flow Range: The measurable flow range depends on the meter technology and size:

- Minimum Detectable Flow: Varies from 0.1 to 5 SFPS depending on technology

- Maximum Flow: Limited by velocity constraints, typically 100-300 SFPS

- Turndown Ratio: The ratio of maximum to minimum measurable flow

Response Time and Dynamic Performance

Response Time: The time required for a compressed air flow meter to respond to flow changes is critical for control applications and leak detection systems. Response times vary by technology:

- Thermal Mass Meters: 1-5 seconds typical

- Vortex Meters: 0.5-2 seconds typical

- Ultrasonic Meters: 0.1-1 second typical

- Differential Pressure: 0.1-0.5 seconds typical

Dynamic Range: The ability to accurately measure rapidly changing flow rates is important for applications with variable demand patterns. Modern digital signal processing enhances dynamic performance through:

- Adaptive filtering algorithms

- Predictive flow calculations

- Noise reduction techniques

- Trend analysis capabilities

Power Requirements and Output Specifications

Power Supply Options: Compressed air flow meters accommodate various power supply configurations:

- 24 VDC: Most common for industrial applications

- 12 VDC: Used for mobile or low-power applications

- 115/230 VAC: Available for permanent installations

- Battery Power: For temporary installations or remote locations

- Loop Power: Derived from 4-20 mA current loops

Output Signal Specifications: Standard output signals facilitate integration with control and monitoring systems:

[Table: Standard Output Signal Specifications]

| Output Type | Signal Range | Accuracy | Load Requirements |

|---|---|---|---|

| 4-20 mA | 4.0-20.0 mA | ±0.1% FS | 0-500 Ω |

| 0-10 VDC | 0.0-10.0 V | ±0.1% FS | >1kΩ |

| Pulse | 0.1-10,000 Hz | ±0.01% | >10kΩ |

| Digital | Various protocols | N/A | Protocol dependent |

Advantages and Benefits

The implementation of compressed air flow meters in industrial facilities provides numerous advantages that extend far beyond simple flow measurement. These benefits contribute to improved operational efficiency, cost reduction, and enhanced system reliability.

Energy Management and Cost Reduction

Energy Consumption Monitoring: Compressed air systems typically consume 10-30% of industrial facility electrical energy. Implementing comprehensive flow measurement enables facilities to:

- Identify high-consumption equipment and processes

- Establish baseline consumption patterns

- Monitor energy efficiency improvements over time

- Implement demand-based control strategies

- Optimize compressor loading and sequencing

Quantifiable Cost Savings: Studies have shown that facilities implementing compressed air monitoring systems achieve average energy savings of 15-25%. For a typical industrial facility with compressed air costs of $50,000 annually, this translates to potential savings of $7,500-$12,500 per year.

Leak Detection and Quantification: Compressed air leaks represent one of the largest sources of waste in pneumatic systems. Advanced thermal mass flow meters enable:

- Continuous monitoring of baseline consumption

- Automated leak detection alerts

- Quantification of leak rates for prioritized repairs

- Verification of repair effectiveness

- Long-term leak trend analysis

Operational Efficiency Improvements

System Optimization: Real-time flow data enables operators to optimize system performance through:

- Right-sizing compressor capacity to match actual demand

- Implementing variable speed drive control based on real consumption

- Balancing distribution system pressure drops

- Optimizing equipment staging and sequencing

- Improving system load factor and efficiency

Predictive Maintenance: Continuous flow monitoring provides valuable data for predictive maintenance programs:

- Early detection of equipment performance degradation

- Trending analysis to predict maintenance requirements

- Optimization of maintenance schedules based on actual usage

- Reduction of unplanned downtime through proactive interventions

[Image: Dashboard screenshot showing compressed air system performance metrics and trends]

Process Control and Quality Improvements

Consistent Process Parameters: Many manufacturing processes require precise compressed air flow rates for optimal quality and efficiency. Flow meters enable:

- Closed-loop flow control for critical processes

- Real-time process optimization based on actual consumption

- Quality assurance through consistent air delivery

- Reduced product defects due to air supply variations

- Enhanced process repeatability and control

Data-Driven Decision Making: Comprehensive flow data supports informed decision-making for:

- Capital equipment investments

- Process improvement initiatives

- Energy efficiency projects

- Facility expansion planning

- Operational cost allocation

Regulatory Compliance and Reporting

Environmental Reporting: Many facilities must report energy consumption and greenhouse gas emissions. Compressed air flow meters provide:

- Accurate energy consumption data for reporting

- Carbon footprint calculations based on actual usage

- Documentation for energy efficiency programs

- Verification of environmental improvement claims

- Support for sustainability initiatives

Industry Standards Compliance: Various industry standards require or recommend compressed air monitoring:

- ISO 50001 Energy Management Systems

- ISO 14001 Environmental Management Systems

- ASME Energy Assessment Standards

- Local utility energy efficiency programs

- Government energy reporting requirements

Limitations and Challenges

While compressed air flow meters offer significant benefits, understanding their limitations and potential challenges is essential for successful implementation and operation. Proper awareness of these factors enables better selection, installation, and maintenance practices.

Technology-Specific Limitations

Thermal Mass Flow Meters: Despite their popularity for compressed air applications, thermal mass flow meters have several limitations:

- Contamination Sensitivity: Oil vapors, moisture, and particulates can coat thermal sensors, affecting accuracy and requiring frequent cleaning

- Calibration Drift: Thermal sensors may experience calibration drift over time, requiring periodic recalibration

- Flow Profile Sensitivity: Performance can be affected by turbulent or asymmetric flow profiles

- Temperature Limitation: Extreme temperatures can affect sensor accuracy and electronic stability

Vortex Flow Meters: These meters face specific challenges in compressed air applications:

- Minimum Flow Requirements: Vortex meters require minimum Reynolds numbers for reliable vortex generation

- Vibration Sensitivity: External vibrations can interfere with vortex detection

- Pressure Drop: The bluff body creates permanent pressure loss in the system

- Turndown Limitations: Lower turndown ratios compared to thermal technologies

Ultrasonic Flow Meters: Ultrasonic technology presents unique challenges:

- Acoustic Coupling: Clamp-on meters require proper acoustic coupling to pipe walls

- Pipe Condition Dependency: Performance affected by pipe material, thickness, and condition

- Installation Complexity: Requires precise sensor positioning and calibration

- Cost Considerations: Generally higher initial cost compared to other technologies

Installation and Environmental Challenges

Straight Pipe Requirements: Most flow meter technologies require adequate straight pipe runs upstream and downstream for accurate measurement:

- Upstream Requirements: Typically 10-20 pipe diameters of straight pipe

- Downstream Requirements: Usually 5-10 pipe diameters minimum

- Space Constraints: Industrial facilities may lack adequate straight pipe runs

- Retrofit Limitations: Existing installations may not accommodate proper placement

Environmental Factors: Harsh industrial environments present ongoing challenges:

- Temperature Fluctuations: Rapid temperature changes affect measurement stability

- Moisture and Condensation: Water dropout can damage electronics and affect accuracy

- Chemical Contamination: Corrosive substances in compressed air can damage sensors

- Electromagnetic Interference: Industrial electrical equipment can interfere with sensitive electronics

[Table: Environmental Challenge Mitigation Strategies]

| Challenge | Impact | Mitigation Strategy |

|---|---|---|

| Temperature Variations | ±2-5% accuracy loss | Thermal insulation, compensation algorithms |

| Moisture Content | Sensor degradation | Drainage systems, moisture-resistant designs |

| Oil Contamination | Sensor fouling | Filtration systems, regular cleaning |

| EMI Interference | Signal noise | Shielded cables, grounding systems |

| Vibration | False readings | Vibration dampening, sensor isolation |

Maintenance and Operational Challenges

Calibration Requirements: Maintaining accuracy requires ongoing attention to calibration:

- Drift Compensation: Sensors may drift over time, requiring periodic verification

- Reference Standard Requirements: Calibration requires traceable reference standards

- Downtime Implications: Calibration procedures may require system shutdown

- Cost Considerations: Professional calibration services represent ongoing costs

Maintenance Accessibility: Some installations present maintenance challenges:

- Physical Access: Meters installed in difficult-to-reach locations

- System Shutdown Requirements: Maintenance may require compressed air system shutdown

- Specialized Tools: Some meters require specialized tools or software for maintenance

- Training Requirements: Maintenance personnel need specific training for different technologies

Economic and Technical Considerations

Total Cost of Ownership: Initial purchase price represents only part of the total investment:

- Installation Costs: Professional installation, piping modifications, electrical work

- Commissioning Expenses: System setup, calibration, and integration

- Operating Costs: Power consumption, communication infrastructure

- Maintenance Costs: Regular calibration, cleaning, and component replacement

Integration Complexity: Modern facilities require sophisticated integration:

- Communication Protocols: Multiple protocols may be required for different systems

- Data Management: Large volumes of data require proper storage and analysis systems

- Software Integration: Meters must integrate with existing SCADA and energy management systems

- Cybersecurity: Network-connected devices introduce potential security vulnerabilities

Comparison with Alternative Flow Measurement Technologies

Selecting the optimal flow measurement technology for compressed air applications requires understanding the relative strengths and weaknesses of available alternatives. This comparison helps engineers and facility managers make informed decisions based on specific application requirements and constraints.

Technology Performance Comparison

Accuracy and Reliability: Different technologies exhibit varying performance characteristics across different operating conditions:

[Table: Comprehensive Technology Comparison]

| Technology | Accuracy | Repeatability | Turndown | Pressure Drop | Maintenance |

|---|---|---|---|---|---|

| Thermal Mass | ±1-2% | ±0.2% | 100:1 | Minimal | Low |

| Vortex | ±1-1.5% | ±0.1% | 20:1 | Low-Medium | Low |

| Ultrasonic | ±1-2% | ±0.2% | 40:1 | None | Medium |

| Differential Pressure | ±1-2.5% | ±0.1% | 4:1 | High | Medium |

| Coriolis | ±0.5-1% | ±0.05% | 40:1 | Medium | Medium |

| Turbine | ±0.5-1% | ±0.1% | 10:1 | Medium | High |

Operating Range Capabilities: Each technology has distinct operating range limitations:

Thermal Mass Flow Meters: Excel in low-flow applications with exceptional sensitivity and wide turndown ratios. However, they may struggle with very high-velocity applications and require careful consideration of contamination effects.

Vortex Flow Meters: Perform well in medium to high-flow applications but require minimum flow velocities for reliable operation. They offer good accuracy and digital output signals but have limited turndown capability.

Ultrasonic Flow Meters: Provide excellent versatility with clamp-on installation options and no pressure drop. However, they may have accuracy limitations at very low flow rates and require proper acoustic coupling.

Cost Considerations

Initial Investment Comparison: The total initial investment includes meter cost, installation expenses, and ancillary equipment:

- Thermal Mass Meters: Medium initial cost with moderate installation complexity

- Vortex Meters: Low to medium initial cost with standard installation requirements

- Ultrasonic Meters: Medium to high initial cost, but potentially lower installation costs for clamp-on versions

- Differential Pressure: Low initial cost but may require additional pressure transmitters and impulse piping

- Coriolis Mass Flow Meters: High initial cost but exceptional accuracy and dual-parameter measurement

Life Cycle Cost Analysis: Total cost of ownership extends beyond initial purchase:

[Video: Life cycle cost analysis demonstration for different flow meter technologies]

Operating Costs: Include power consumption, communication expenses, and operational overhead:

- Power consumption varies from 5-25 watts depending on technology and features

- Communication infrastructure costs for network integration

- Training expenses for operations and maintenance personnel

- Software licensing for advanced diagnostic and analysis capabilities

Maintenance Costs: Ongoing maintenance expenses significantly impact total cost of ownership:

- Calibration services typically cost $500-2000 per meter depending on technology and accuracy requirements

- Component replacement costs vary by technology complexity

- Downtime costs for maintenance activities can be substantial in critical applications

Application-Specific Considerations

Leak Detection Applications: For compressed air leak detection and energy management:

Recommended: Thermal mass flow meters excel due to their low-flow sensitivity, wide turndown ratios, and direct mass measurement capability.

Alternative: Ultrasonic flow meters offer non-intrusive installation for retrofit applications.

High-Pressure Applications: Systems operating above 200 PSIG require robust construction:

Recommended: Differential pressure meters handle high pressures well and are cost-effective.

Alternative: Vortex meters offer good high-pressure performance with digital output.

Critical Process Control: Applications requiring precise flow control and exceptional accuracy:

Recommended: Coriolis mass flow meters provide the highest accuracy and excellent repeatability.

Alternative: Well-calibrated thermal mass flow meters offer good performance at lower cost.

Technology Selection Matrix

Decision Criteria Framework: Selecting optimal technology requires evaluating multiple criteria:

Primary Factors:

- Accuracy requirements

- Flow range and turndown needs

- Pressure and temperature conditions

- Installation constraints

- Budget limitations

Secondary Factors:

- Maintenance requirements

- Communication needs

- Environmental conditions

- Existing system compatibility

- Future expansion plans

Application Examples:

Large Industrial Facility Energy Management:

- Technology: Thermal mass flow meters

- Rationale: Wide turndown, low maintenance, direct mass measurement

- Typical Savings: 15-25% energy reduction

Critical Manufacturing Process Control:

- Technology: Coriolis mass flow meters

- Rationale: Highest accuracy, excellent repeatability, dual-parameter measurement

- Typical Performance: ±0.5% accuracy, ±0.05% repeatability

Retrofit Monitoring Installation:

- Technology: Clamp-on ultrasonic meters

- Rationale: Non-intrusive installation, no system shutdown required

- Typical Installation: 2-4 hours per meter location

Selection and Buying Guide

Selecting the appropriate compressed air flow meter requires systematic evaluation of technical requirements, operational constraints, and economic considerations. This comprehensive guide provides a structured approach to making optimal technology and vendor selections.

Requirements Assessment

Flow Measurement Objectives: Clearly define the primary purposes for flow measurement:

Energy Management: Focus on accuracy across wide flow ranges, long-term stability, and integration with energy management systems. Recommended features include:

- Wide turndown ratios (50:1 or better)

- Built-in pressure and temperature compensation

- Data logging capabilities

- Communication protocols for SCADA integration

- Low maintenance requirements

Process Control: Emphasize measurement accuracy, fast response times, and reliable control signals:

- High accuracy (±1% or better)

- Fast response times (1 second or less)

- 4-20 mA analog outputs with HART protocol

- Fail-safe operation modes

- Redundancy options for critical applications

Cost Allocation: Prioritize accuracy, data integrity, and audit trail capabilities:

- Measurement uncertainty within ±2%

- Tamper-evident designs

- Data logging with time stamps

- Communication security features

- Calibration traceability documentation

System Requirements Analysis: Document the specific operating conditions and constraints:

[Table: System Requirements Checklist]

| Parameter | Specification | Impact on Selection |

|---|---|---|

| Flow Range | Min/Max SCFM | Determines meter size and technology |

| Pressure Range | Operating PSIG | Affects meter construction requirements |

| Temperature Range | Operating °F | Influences sensor technology selection |

| Pipe Size | Inches/mm | Determines meter sizing and installation |

| Accuracy Requirements | % of reading | Drives technology selection |

| Installation Constraints | Space limitations | Affects meter type and configuration |

| Power Availability | VDC/VAC options | Determines power supply requirements |

| Communication Needs | Protocols required | Influences electronic specifications |

Technology Selection Process

Performance Requirements Evaluation: Match meter capabilities to application needs:

High-Accuracy Applications (±1% or better):

- First Choice: Coriolis mass flow meters for ultimate accuracy

- Alternative: Thermal mass flow meters with premium calibration

- Consideration: Higher initial cost but superior long-term performance

Wide Turndown Requirements (>20:1):

- Primary Recommendation: Thermal mass flow meters (100:1 typical)

- Secondary Option: Ultrasonic meters (40:1 typical)

- Avoid: Differential pressure meters (4:1 typical limitation)

Low-Flow Sensitivity Applications:

- Optimal Choice: Thermal mass flow meters

- Advantage: Excellent sensitivity to small flow changes

- Benefit: Early leak detection capabilities

Budget-Conscious Applications:

- Cost-Effective: Vortex meters for medium to high flows

- Alternative: Differential pressure meters with electronic transmitters

- Consideration: Balance initial cost against accuracy requirements

Vendor Evaluation Criteria

Technical Capabilities: Assess vendor technical expertise and support:

Engineering Support: Evaluate vendor capabilities in:

- Application engineering assistance

- Custom configuration services

- Integration support and testing

- Commissioning and startup services

- Technical training programs

Product Quality: Consider manufacturing standards and quality systems:

- ISO 9001 quality management certification

- Calibration laboratory accreditation

- Product testing and validation procedures

- Quality assurance documentation

- Warranty terms and conditions

Service and Support: Evaluate long-term support capabilities:

- Local technical support availability

- Response time commitments

- Spare parts availability and pricing

- Repair and calibration services

- Software updates and enhancements

Economic Analysis

Total Cost of Ownership Calculation: Develop comprehensive cost models including:

[Table: Cost Analysis Worksheet]

| Cost Category | Year 1 | Year 2-5 | Year 6-10 | Total |

|---|---|---|---|---|

| Initial Purchase | $5,000 | $0 | $0 | $5,000 |

| Installation | $2,000 | $0 | $0 | $2,000 |

| Commissioning | $1,500 | $0 | $0 | $1,500 |

| Annual Maintenance | $500 | $2,000 | $2,500 | $5,000 |

| Calibration | $0 | $2,000 | $2,000 | $4,000 |

| Power Consumption | $200 | $800 | $1,000 | $2,000 |

| Total | $9,200 | $4,800 | $5,500 | $19,500 |

Return on Investment Analysis: Calculate payback periods based on expected savings:

- Energy cost reductions from leak detection and system optimization

- Maintenance cost savings through predictive maintenance

- Process efficiency improvements and quality enhancements

- Reduced downtime and emergency repair costs

- Regulatory compliance cost avoidance

Installation and Setup Requirements

Proper installation is critical for achieving optimal performance and long-term reliability from compressed air flow meters. This section provides comprehensive guidance on installation planning, execution, and commissioning procedures.

Pre-Installation Planning

Site Survey and Assessment: Conduct thorough evaluation of installation locations:

Piping System Analysis: Document existing piping configuration including:

- Pipe material, size, and wall thickness

- Insulation and external coatings

- Accessibility for installation and maintenance

- Proximity to other equipment and interference sources

- Available straight pipe runs upstream and downstream

Environmental Conditions: Assess installation environment factors:

- Ambient temperature range and variations

- Humidity levels and condensation potential

- Chemical exposure and corrosive atmosphere

- Vibration sources and mechanical stress

- Electrical interference and grounding requirements

Infrastructure Requirements: Verify availability of supporting infrastructure:

- Electrical power supply and distribution

- Communication network connectivity

- Mounting hardware and support structures

- Safety systems and emergency procedures

- Access platforms and maintenance facilities

Installation Procedures

Mechanical Installation: Follow manufacturer specifications for proper mechanical mounting:

Insertion Meters: For meters that require insertion into the pipe:

- Mark insertion depth according to pipe size and manufacturer specifications

- Install isolation valve and retraction mechanism if specified

- Ensure proper sensor orientation and alignment

- Apply appropriate thread sealant or gasket materials

- Torque connections to specified values

Inline Meters: For meters installed directly in the pipe run:

- Ensure adequate straight pipe runs upstream and downstream

- Install with proper flow direction orientation

- Provide adequate support to prevent pipe stress

- Install bypass valving if required for maintenance

- Apply appropriate gasket materials and joint sealants

[Image: Proper installation configuration showing straight pipe requirements and meter positioning]

Clamp-On Meters: For non-intrusive ultrasonic installations:

- Select optimal pipe section with uniform wall thickness

- Prepare pipe surface by removing insulation and cleaning

- Apply acoustic coupling compound as specified

- Install transducers with proper spacing and alignment

- Secure sensor cables and provide strain relief

Electrical Installation

Power Supply Connections: Install appropriate power supply systems:

DC Power Systems: Most compressed air flow meters operate on 24 VDC power:

- Install regulated power supplies with adequate capacity

- Provide proper grounding and electrical isolation

- Use appropriate cable types for industrial environments

- Install surge protection and overcurrent protection

- Document wiring diagrams and connection points

Signal Wiring: Install signal cables according to best practices:

- Use shielded cables for analog signals to minimize interference

- Maintain separation from power cables and high-current conductors

- Install proper cable supports and strain relief

- Provide adequate service loops for maintenance access

- Label all cables and termination points clearly

Communication Networks: Connect meters to control and monitoring systems:

- Configure network addresses and communication parameters

- Test communication links and verify data transmission

- Install network infrastructure equipment as required

- Implement cybersecurity measures for network-connected devices

- Document network configuration and troubleshooting procedures

Commissioning and Startup

Initial Configuration: Program meter settings for specific application:

Basic Parameters: Configure fundamental operating parameters:

- Flow units and engineering scale factors

- Pressure and temperature compensation settings

- Output signal ranges and scaling

- Display preferences and local indication

- Alarm and diagnostic settings

Advanced Settings: Configure application-specific features:

- Damping and filtering parameters for stable operation

- Totalizer and batch functions if required

- Data logging intervals and storage capacity

- Communication protocol settings and addresses

- Security access codes and user permissions

Calibration Verification: Verify measurement accuracy:

- Perform zero flow verification with flow stopped

- Conduct span verification using reference flow standards

- Check linearity across the measurement range

- Verify temperature and pressure compensation

- Document calibration results and certificates

[Video: Complete commissioning procedure demonstration for thermal mass flow meter]

Performance Testing: Validate system performance:

- Test all output signals and communication functions

- Verify alarm and diagnostic operations

- Conduct leak simulation tests if applicable

- Check integration with control and monitoring systems

- Perform acceptance testing according to specifications

Operation and Best Practices

Effective operation of compressed air flow meters requires understanding proper operating procedures, routine monitoring practices, and performance optimization techniques. This section provides comprehensive guidance for maximizing meter performance and system reliability.

Operating Procedures

Startup Procedures: Follow systematic startup sequence for reliable operation:

Pre-Startup Checks: Verify system readiness before energizing equipment:

- Confirm all installation work is complete and properly documented

- Verify electrical connections and grounding systems

- Check mechanical mounting and pipe connections

- Confirm communication network connectivity

- Review safety procedures and emergency shutdown protocols

Initial Startup Sequence: Follow proper sequence to avoid equipment damage:

- Apply power and verify normal startup indication

- Allow stabilization period for thermal equilibrium

- Verify zero flow reading with no flow condition

- Gradually introduce flow and monitor response

- Check all output signals and communication functions

Normal Operating Procedures: Establish routine operating practices:

- Monitor key performance indicators regularly

- Review diagnostic status messages and alarms

- Maintain operation log books with key parameters

- Perform routine visual inspections of equipment

- Follow established procedures for parameter changes

Performance Monitoring

Key Performance Indicators: Monitor critical parameters for optimal performance:

Primary Measurements: Track fundamental flow measurement parameters:

- Flow rate readings and trends over time

- Totalizer values and consumption patterns

- Temperature and pressure compensation values

- System efficiency calculations and benchmarks

- Alarm frequency and diagnostic messages

Secondary Parameters: Monitor supporting measurements for system health:

- Sensor temperature readings and stability

- Power consumption and electrical parameters

- Communication status and data quality indicators

- Environmental conditions and their effects

- Calibration drift indicators and timing

[Table: Performance Monitoring Checklist]

| Parameter | Frequency | Normal Range | Action Required |

|---|---|---|---|

| Flow Rate | Continuous | Design range | Investigate deviations |

| Temperature | Daily | ±5°F of setpoint | Check compensation |

| Pressure | Daily | Design pressure ±10% | Verify system operation |

| Diagnostics | Weekly | No active alarms | Address all warnings |

| Calibration | Annually | Within specification | Schedule recalibration |

Trending and Analysis: Implement systematic data analysis procedures:

- Establish baseline performance benchmarks

- Identify normal operating patterns and cycles

- Detect gradual performance degradation trends

- Compare actual performance against design specifications

- Generate regular performance reports and summaries

Optimization Techniques

System Efficiency Improvements: Implement strategies to maximize system performance:

Flow Profile Optimization: Ensure optimal flow conditions for accurate measurement:

- Maintain adequate straight pipe runs as specified

- Install flow straighteners if necessary for disturbed flows

- Monitor and address sources of flow turbulence

- Optimize piping configuration to minimize pressure drops

- Consider flow conditioning devices for challenging installations

Environmental Control: Manage environmental factors affecting performance:

- Control temperature variations through insulation or heating

- Implement moisture management systems to prevent condensation

- Protect equipment from vibration and mechanical stress

- Maintain proper grounding and electrical isolation

- Shield sensitive electronics from electromagnetic interference

Calibration Management: Maintain measurement accuracy through proper calibration practices:

- Establish calibration schedules based on application criticality

- Use traceable reference standards for all calibrations

- Document calibration procedures and maintain records

- Implement drift monitoring between calibration intervals

- Consider in-situ calibration techniques where applicable

Integration with Control Systems

SCADA Integration: Connect compressed air flow meters to supervisory control systems:

Data Acquisition: Configure data collection and storage systems:

- Set appropriate data sampling rates for application needs

- Implement data validation and quality checks

- Configure alarm limits and notification systems

- Establish data backup and archive procedures

- Integrate with existing energy management systems

Control Applications: Utilize flow measurement data for automatic control:

- Implement demand-based compressor control strategies

- Configure automatic leak detection and notification systems

- Develop energy optimization algorithms based on real-time data

- Integrate with facility automation and building management systems

- Establish predictive maintenance scheduling based on usage patterns

Reporting and Analytics: Generate meaningful reports from flow measurement data:

- Create automated energy consumption reports

- Develop cost allocation reports for different departments

- Generate efficiency trending and benchmarking reports

- Implement predictive analytics for maintenance planning

- Provide regulatory compliance documentation and reporting

Maintenance and Troubleshooting

Proper maintenance is essential for ensuring long-term accuracy, reliability, and service life of compressed air flow meters. This section provides comprehensive guidance on preventive maintenance procedures, troubleshooting techniques, and repair practices.

Preventive Maintenance Programs

Routine Maintenance Tasks: Establish systematic maintenance procedures:

Daily Inspection Items: Quick checks performed during routine operations:

- Visual inspection of meter housing and connections

- Verification of display readings and normal operation

- Check for unusual noises, vibrations, or physical damage

- Review diagnostic messages and alarm status

- Document any abnormal conditions or changes

Weekly Maintenance Tasks: More detailed inspection and verification procedures:

- Clean display windows and external surfaces

- Check electrical connections and cable condition

- Verify communication system operation and data transmission

- Review trending data for unusual patterns or drift

- Inspect mounting hardware and pipe connections

Monthly Maintenance Activities: Comprehensive system checks and testing:

- Perform zero flow verification tests

- Check calibration stability using reference methods

- Inspect and clean sensor elements as required

- Verify alarm and safety system functions

- Update maintenance logs and documentation

[Table: Preventive Maintenance Schedule]

| Task | Frequency | Duration | Personnel Required |

|---|---|---|---|

| Visual Inspection | Daily | 5 minutes | Operator |

| Display Cleaning | Weekly | 10 minutes | Technician |

| Connection Check | Monthly | 30 minutes | Technician |

| Calibration Verification | Quarterly | 2 hours | Specialist |

| Full Calibration | Annually | 4 hours | Certified Technician |

13.2 Calibration Procedures

Calibration Planning: Develop systematic calibration management:

Reference Standards: Establish traceable calibration standards:

- Primary standards: Master meters with certified accuracy

- Secondary standards: Working standards for routine verification

- Portable calibrators: Field-deployable calibration equipment

- Documentation: Maintain calibration certificates and traceability

- Scheduling: Plan calibrations to minimize system downtime

Calibration Procedures: Follow systematic calibration protocols:

Pre-Calibration Checks: Verify system readiness:

- Review maintenance history and previous calibration records

- Inspect meter condition and verify proper installation

- Check environmental conditions and system stability

- Verify reference standard calibration and certification

- Prepare calibration documentation and forms

Calibration Execution: Perform systematic calibration sequence:

- Establish zero flow condition and verify zero reading

- Apply known flow rates across the measurement range

- Record meter readings at each calibration point

- Calculate measurement errors and uncertainty values

- Adjust meter calibration if necessary and within limits

Post-Calibration Activities: Complete calibration documentation:

- Verify proper meter operation after calibration adjustments

- Update meter configuration and calibration factors

- Complete calibration certificates and documentation

- Update maintenance management system records

- Schedule next calibration based on drift characteristics

Troubleshooting Procedures

Systematic Troubleshooting Approach: Follow logical diagnostic procedures:

Problem Identification: Document symptoms and operating conditions:

- Record specific error messages or fault codes

- Note environmental conditions when problems occur

- Document recent changes to system or configuration

- Identify affected measurement parameters or outputs

- Collect diagnostic data and system logs

Common Problems and Solutions: Address typical operational issues:

Measurement Accuracy Issues:

- Symptom: Readings consistently high or low

- Causes: Calibration drift, sensor contamination, installation problems

- Solutions: Recalibration, sensor cleaning, flow profile improvement

- Prevention: Regular calibration, filtration systems, proper installation

Communication Problems:

- Symptom: Loss of communication or intermittent data

- Causes: Network issues, cable problems, configuration errors

- Solutions: Check connections, verify settings, test communication links

- Prevention: Regular cable inspection, proper installation practices

Environmental Issues:

- Symptom: Erratic readings or frequent alarms

- Causes: Temperature effects, moisture problems, vibration

- Solutions: Environmental controls, sensor protection, isolation mounting

- Prevention: Proper site selection, environmental monitoring

[Image: Troubleshooting flowchart showing diagnostic decision tree for common problems]

Repair and Replacement

Component Replacement: Handle component failures systematically:

Sensor Replacement: Follow proper procedures for critical components:

- Document existing configuration and calibration data

- Obtain proper replacement parts with matching specifications

- Follow manufacturer procedures for safe removal and installation

- Perform complete calibration after component replacement

- Update maintenance records with replacement information

Electronics Replacement: Handle electronic component failures:

- Power down system safely and verify lockout procedures

- Document existing configuration settings and parameters

- Install replacement electronics with proper ESD protection

- Restore configuration settings and verify proper operation

- Perform functional testing of all inputs and outputs

Upgrade Considerations: Plan for technology improvements:

- Evaluate benefits of upgrading to newer technology

- Consider improved accuracy, features, or communication capabilities

- Plan upgrade projects to minimize system downtime

- Provide training for new equipment operation and maintenance

- Update documentation and procedures for new equipment

Cost Analysis and Return on Investment

Understanding the economic aspects of compressed air flow meter implementation is crucial for justifying investments and maximizing returns. This section provides comprehensive analysis of costs, savings potential, and financial benefits.

Total Cost of Ownership Analysis

Initial Investment Components: Comprehensive cost breakdown for flow meter projects:

[Table: Initial Investment Cost Breakdown]

| Cost Component | Typical Range | Percentage of Total |

|---|---|---|

| Flow Meter Hardware | $3,000-$15,000 | 40-60% |

| Installation Labor | $1,000-$5,000 | 15-25% |

| Electrical/Communication | $500-$2,500 | 8-15% |

| Commissioning | $500-$2,000 | 5-12% |

| Training | $500-$1,500 | 3-8% |

| Project Management | $500-$2,000 | 5-10% |

| Total Initial Investment | $6,000-$28,000 | 100% |

Operating Costs: Ongoing expenses throughout equipment lifecycle:

Annual Operating Expenses: Regular costs for system operation:

- Power consumption: $50-$200 per meter annually

- Communication services: $100-$500 for network connectivity

- Software licensing: $200-$1,000 for advanced analytics

- Insurance and risk management: 1-2% of equipment value

- Administrative overhead: $200-$500 annually

Maintenance Costs: Regular and periodic maintenance expenses:

- Routine maintenance: $200-$800 annually

- Calibration services: $500-$2,000 every 1-2 years

- Component replacement: $300-$1,500 every 3-5 years

- Emergency repairs: $500-$3,000 per incident

- Upgrade and modernization: 10-20% of initial cost every 10 years

Savings and Benefits Quantification

Energy Cost Savings: Primary source of economic benefits from flow measurement:

Leak Detection Savings: Quantifiable benefits from identifying and repairing system leaks:

- Typical leak rates: 10-30% of total compressed air production

- Energy cost of leaks: $2,000-$10,000 annually for typical facilities

- Leak detection effectiveness: 70-90% reduction in leak rates

- Annual savings potential: $1,500-$9,000 from leak elimination

System Optimization Savings: Benefits from improved system efficiency:

- Compressor efficiency improvements: 5-15% energy reduction

- Pressure optimization: 2-8% energy savings per PSI reduction

- Load management: 10-25% reduction in energy costs

- Equipment right-sizing: 15-40% savings on new equipment

[Table: Energy Savings Calculation Example]

| Facility Parameter | Current State | Optimized State | Annual Savings |

|---|---|---|---|

| Compressed Air Cost | $50,000 | $37,500 | $12,500 |

| Leak Rate | 25% | 5% | $8,000 |

| System Efficiency | 75% | 85% | $3,500 |

| Peak Demand Charges | $15,000 | $12,000 | $3,000 |

| Total Annual Savings | $27,000 |

Operational Benefits: Additional cost savings and productivity improvements:

Maintenance Cost Reduction: Predictive maintenance benefits:

- Reduced unplanned downtime: $5,000-$25,000 annually

- Extended equipment life: 15-25% improvement

- Optimized maintenance scheduling: 10-20% cost reduction

- Improved spare parts management: 5-15% inventory reduction

Process Efficiency Improvements: Manufacturing and quality benefits:

- Reduced product defects due to consistent air pressure

- Improved equipment performance and reliability

- Enhanced process control and repeatability

- Reduced warranty claims and customer complaints

Return on Investment Calculations

Payback Period Analysis: Calculate time to recover initial investment:

Simple Payback Calculation: Payback Period = Initial Investment / Annual Savings

Example Calculation:

- Initial Investment: $15,000 for comprehensive monitoring system

- Annual Savings: $12,000 from energy optimization

- Simple Payback: 15,000 / 12,000 = 1.25 years

Net Present Value Analysis: Consider time value of money:

NPV Calculation Parameters:

- Discount rate: 8-12% typical for industrial projects

- Project life: 10-15 years for flow measurement systems

- Annual cash flows: Energy savings minus operating costs

- Terminal value: Residual equipment value at project end

[Table: 10-Year NPV Analysis Example]

| Year | Initial Cost | Operating Cost | Energy Savings | Net Cash Flow | Present Value |

|---|---|---|---|---|---|

| 0 | ($15,000) | $0 | $0 | ($15,000) | ($15,000) |

| 1-2 | $0 | ($1,000) | $12,000 | $11,000 | $19,174 |

| 3-5 | $0 | ($1,500) | $13,000 | $11,500 | $26,234 |

| 6-10 | $0 | ($2,000) | $14,000 | $12,000 | $32,446 |

| NPV | $62,854 |

Financial Justification Strategies

Business Case Development: Create compelling financial justifications:

Risk Mitigation Benefits: Quantify risk reduction value:

- Avoided costs from system failures and downtime

- Insurance premium reductions for improved safety

- Regulatory compliance cost avoidance

- Environmental liability reduction

Strategic Benefits: Consider long-term strategic advantages:

- Improved competitiveness through cost reduction

- Enhanced sustainability and environmental performance

- Technology platform for future expansion

- Data foundation for Industry 4.0 initiatives

Financing Options: Explore alternative financing approaches:

- Equipment leasing to preserve capital

- Performance contracting with guaranteed savings

- Utility rebates and incentive programs

- Government grants for energy efficiency projects

Industry Applications and Case Studies

Compressed air flow meters find applications across diverse industries, each with unique requirements and challenges. This section examines specific applications and presents detailed case studies demonstrating successful implementations.

Manufacturing Industries

Automotive Manufacturing: Critical applications for precision and efficiency:

Production Line Monitoring: Flow meters enable optimization of pneumatic systems:

- Assembly line tool monitoring for consistent torque specifications

- Paint booth air flow control for quality finish application

- Conveyor system pneumatic controls for material handling

- Brake and suspension testing equipment air supply verification

- Clean room air flow monitoring for contamination control

Case Study: Major Automotive Plant Energy Optimization:

- Facility: 2.5 million square foot assembly plant

- Challenge: $850,000 annual compressed air costs with suspected inefficiencies

- Solution: 45 thermal mass flow meters installed throughout facility

- Results: 28% energy cost reduction saving $238,000 annually

- Payback: 14 months on $82,000 investment

Food and Beverage Processing: Sanitary and precision applications:

Process Applications: Critical flow measurement for food safety:

- Pneumatic conveying systems for ingredient handling

- Packaging equipment air supply for consistent operation

- Cleaning system air flow for CIP (Clean-In-Place) operations

- Fermentation tank pressure control air supply

- Quality control testing equipment air supply

Pharmaceutical Manufacturing: High precision and validation requirements:

Critical Applications: Stringent accuracy and documentation needs:

- Tablet coating equipment air flow control

- Sterile filling line compressed air monitoring

- Laboratory instrument air supply verification

- Clean room differential pressure control

- Validation protocol documentation for regulatory compliance

Process Industries

Chemical Processing: Challenging environments with specialized requirements:

Safety-Critical Applications: Flow measurement in hazardous locations:

- Reactor cooling system air supply monitoring

- Emergency shutdown system pneumatic controls

- Catalyst regeneration air flow measurement

- Flare system purge air monitoring

- Instrument air supply backup systems

[Video: Chemical plant compressed air monitoring system installation and operation]

Petrochemical Refineries: High-pressure and extreme temperature applications:

Refinery Applications: Robust measurement solutions required:

- Crude oil pumping system pneumatic controls

- Distillation column instrument air supply

- Catalyst handling pneumatic conveying systems

- Steam reforming process air flow measurement

- Maintenance tool air supply monitoring

Case Study: Refinery Compressed Air System Optimization:

- Facility: 250,000 barrel per day refinery

- Challenge: Aging compressed air system with high maintenance costs

- Solution: Comprehensive monitoring with 60 flow meters and centralized control

- Technology: Mix of vortex and thermal mass flow meters based on application

- Results: 32% reduction in energy costs and 45% reduction in maintenance

- Additional Benefits: Improved safety and environmental compliance

Utilities and Infrastructure

Power Generation: Critical utility applications:

Power Plant Applications: Reliability and accuracy requirements:

- Coal handling pneumatic conveying systems

- Ash handling compressed air systems

- Instrument air systems for control valves

- Cooling tower air flow monitoring

- Maintenance shop compressed air distribution

Water and Wastewater Treatment: Environmental and efficiency applications:

Treatment Plant Applications: Process optimization and efficiency:

- Aeration system air flow control for biological treatment

- Pneumatic valve actuator air supply monitoring

- Chemical feed system air supply verification

- Sludge handling pneumatic conveying systems

- Laboratory air supply for testing equipment

Commercial Buildings and Facilities

Healthcare Facilities: Critical air quality and reliability requirements:

Medical Air Systems: Life-safety critical applications:

- Medical air compressor system monitoring

- Operating room air supply verification

- Laboratory fume hood air flow measurement

- Sterilization equipment air supply monitoring

- Emergency backup system air flow verification

Data Centers: Precision cooling and environmental control:

Cooling System Applications: Energy efficiency and reliability focus:

- Pneumatic damper control air supply

- Cooling system maintenance air supply

- Precision cooling equipment air flow verification

- Backup system air supply monitoring

- Energy optimization and reporting systems

Specialized Applications

Aerospace and Defense: High precision and reliability requirements:

Critical Applications: Mission-critical performance needs:

- Aircraft testing facility compressed air systems

- Clean room air flow monitoring for satellite assembly

- Wind tunnel compressed air supply systems

- Test equipment air supply verification

- Quality control testing air supply monitoring

Research and Development: Precision measurement for experimental work:

Laboratory Applications: High accuracy and flexibility needs:

- Research equipment air supply monitoring

- Calibration laboratory reference air systems

- Environmental chamber air flow control

- Material testing equipment air supply

- Prototype testing air supply verification

[Image: Research laboratory compressed air monitoring system with multiple flow meters]

Mining and Extraction: Harsh environment applications:

Mining Applications: Rugged and reliable measurement solutions:

- Pneumatic conveying systems for material handling

- Dust suppression system air flow monitoring

- Drilling equipment air supply verification

- Ventilation system air flow measurement

- Safety system compressed air monitoring

Integration with Control Systems

Modern compressed air flow meters must integrate seamlessly with facility control and monitoring systems to provide maximum value. This section covers integration strategies, communication protocols, and system architecture considerations.

Communication Protocols and Interfaces

Industrial Communication Standards: Overview of common protocols used in compressed air monitoring:

Modbus Protocol Family: Most widely adopted industrial communication standard:

- Modbus RTU: Serial communication over RS-485 networks

- Modbus TCP: Ethernet-based communication for modern networks

- Advantages: Universal compatibility, simple implementation, extensive device support

- Applications: Integration with PLCs, SCADA systems, and energy management systems

- Considerations: Limited bandwidth for large systems, security vulnerabilities

Ethernet-Based Protocols: Modern high-speed communication options:

- Ethernet/IP: Allen-Bradley and Rockwell Automation standard

- Profinet: Siemens industrial Ethernet protocol

- EtherCAT: Real-time Ethernet for high-performance applications

- Benefits: High-speed data transfer, advanced diagnostics, web-based interfaces

- Requirements: Managed network infrastructure, cybersecurity considerations

Fieldbus Systems: Traditional industrial network standards:

- Foundation Fieldbus: Process industry standard with power over bus

- DeviceNet: CAN-based network for Allen-Bradley systems

- Profibus: European standard for distributed I/O and drives

- Legacy Considerations: Existing installations, migration strategies

SCADA and HMI Integration

Supervisory Control and Data Acquisition: Connecting flow meters to facility monitoring systems:

Data Point Configuration: Setting up flow meter data in SCADA systems:

- Real-time flow rate measurements and totalized values

- Temperature and pressure compensation parameters

- Diagnostic status information and alarm conditions

- Historical trending data and statistical calculations

- Energy consumption calculations and cost allocation

Alarm and Event Management: Implementing comprehensive monitoring:

- High and low flow rate alarms for leak detection

- Equipment failure notifications and diagnostic alerts

- Calibration due dates and maintenance reminders

- Communication failure detection and recovery procedures

- Historical alarm logging and reporting capabilities

Human Machine Interface Design: Creating effective operator interfaces:

- Real-time dashboard displays with key performance indicators

- Trending charts showing consumption patterns over time

- Equipment status displays with diagnostic information

- Control interfaces for setpoint changes and system configuration

- Mobile-friendly displays for remote monitoring and control

[Table: SCADA Integration Requirements]

| Function | Data Points | Update Rate | Storage Requirements |

|---|---|---|---|

| Real-time Monitoring | 4-8 per meter | 1-10 seconds | 30 days minimum |

| Historical Trending | 2-4 per meter | 1-15 minutes | 2-5 years |

| Alarm Management | 6-12 per meter | Immediate | 1-2 years |

| Reporting | Calculated | Hourly/Daily | 5-10 years |

Energy Management System Integration

Building Management Systems: Integrating with facility automation:

BACnet Integration: Building automation standard protocol:

- Standardized data objects for flow measurement

- Integration with HVAC and lighting control systems

- Energy optimization algorithms using real-time flow data

- Automated reporting for energy management programs

- Integration with utility demand response programs

Energy Information Systems: Connecting to enterprise energy management:

- Automated data collection from multiple flow meters

- Energy cost calculation and allocation by department

- Benchmark comparisons and performance tracking

- Regulatory reporting and compliance documentation

- Integration with utility billing and rate structures

Demand Response Integration: Participating in utility programs:

- Automated load shedding during peak demand periods

- Real-time monitoring of demand charges and costs

- Optimization algorithms for minimum cost operation

- Integration with renewable energy systems

- Participation in grid stabilization programs

Cloud and IoT Integration

Internet of Things Connectivity: Modern connectivity options for flow meters:

Wireless Communication Technologies: Reducing installation costs:

- Wi-Fi: Standard 802.11 protocols for existing networks

- LoRaWAN: Long-range, low-power for distributed systems

- Cellular: 4G/5G connectivity for remote locations

- Bluetooth: Short-range for commissioning and maintenance

- Zigbee: Mesh networking for facility-wide systems

Cloud Platform Integration: Leveraging cloud computing capabilities:

- Data Storage: Scalable storage for historical data

- Analytics: Advanced algorithms for optimization and prediction

- Remote Access: Secure web-based monitoring from anywhere

- Mobile Applications: Smartphone and tablet interfaces

- API Integration: Connection to enterprise software systems

Cybersecurity Considerations: Protecting connected systems:

- Network segmentation and firewall protection

- Encrypted communication channels and authentication

- Regular security updates and patch management

- Access control and user permission management

- Security monitoring and incident response procedures

[Image: Network architecture diagram showing flow meters connected to cloud platforms through various communication methods]

Data Analytics and Machine Learning: Advanced capabilities:

- Predictive maintenance algorithms using flow patterns

- Leak detection using machine learning techniques

- Energy optimization through artificial intelligence

- Pattern recognition for equipment performance

- Automated reporting and recommendation systems

Safety Considerations

Safety is paramount when working with compressed air flow meters and pneumatic systems. This section covers hazard identification, safety procedures, and regulatory compliance requirements.

Hazard Identification and Risk Assessment

Compressed Air System Hazards: Understanding potential dangers:

High Pressure Hazards: Risks associated with pressurized systems:

- Sudden pressure release can cause serious injury or death

- Projectile hazards from failed components or connections

- Noise exposure from high-velocity air discharge

- Whipping hose and line hazards during failures

- Eye and respiratory injuries from air blast exposure

Electrical Hazards: Risks from electrical components:

- Shock and electrocution from improper wiring

- Arc flash hazards during maintenance activities

- Electromagnetic interference with other equipment

- Fire hazards from overheated components

- Lightning strike vulnerability for outdoor installations

Chemical and Contamination Hazards: Risks from air quality issues:

- Oil vapor exposure from compressor contamination

- Particulate inhalation from system contamination

- Moisture and condensation creating slip hazards

- Chemical exposure from cleaning solvents and lubricants

- Asbestos exposure in older pipe insulation materials

Safety Procedures and Protocols

Installation Safety: Safe practices for flow meter installation:

Pre-Installation Safety Planning: Comprehensive safety preparation:

- Conduct job hazard analysis (JHA) for all installation activities

- Verify proper lockout/tagout (LOTO) procedures for system isolation

- Ensure adequate personal protective equipment (PPE) availability

- Confirm emergency response procedures and communication

- Verify proper lifting and rigging equipment for heavy components

System Isolation Procedures: Safe de-energization of compressed air systems:

- Electrical Isolation: Lock out electrical power sources

- Pneumatic Isolation: Close isolation valves and vent pressure

- Verification Testing: Confirm zero energy state before work

- Barrier Installation: Install blanks or line breaks as required

- Communication: Notify all affected personnel of system status

Hot Work Procedures: Safety for welding and cutting operations:

- Obtain hot work permits before any welding or cutting

- Verify atmosphere testing for flammable vapors

- Station fire watch personnel with appropriate extinguishers

- Maintain hot work area isolation and ventilation

- Follow post-work fire watch requirements

Personal Protective Equipment

Standard PPE Requirements: Basic protection for compressed air work:

Eye and Face Protection: Protection from high-pressure air:

- Safety glasses with side shields minimum requirement

- Face shields for high-pressure applications above 100 PSIG

- Goggles for dusty or contaminated environments

- Prescription safety glasses for vision correction needs

- Anti-fog coatings for humid or temperature-varying conditions

Respiratory Protection: Protection from airborne contaminants:

- N95 dust masks for particulate protection

- Half-face respirators for chemical vapor exposure

- Full-face respirators for combined protection needs

- Supplied air systems for confined space work

- Proper fit testing and medical clearance requirements

Hearing Protection: Protection from noise exposure:

- Earplugs for moderate noise levels (85-100 dB)

- Earmuffs for higher noise levels (100+ dB)

- Combination protection for extreme noise environments

- Communication headsets for coordination needs

- Regular audiometric testing for noise-exposed workers

[Table: PPE Selection Matrix]

| Hazard Type | Low Risk | Medium Risk | High Risk |

|---|---|---|---|

| Pressure (PSIG) | 0-30 | 31-150 | 151+ |

| Eye Protection | Safety glasses | Safety glasses + shield | Full face shield |

| Hand Protection | Work gloves | Cut-resistant gloves | Impact gloves |

| Body Protection | Work clothes | Coveralls | Pressure suits |

Regulatory Compliance

OSHA Requirements: Occupational safety standards for compressed air: