Description

ATLU precession vortex (Swirl) flow meter is an ideal instrument for gas measurement in petroleum, chemical, electric power, metallurgy and other industries. This flow meter integrates the functions of flow measurement, temperature and pressure detection. In addition, it can automatically compensate the temperature, pressure and compression factor.

Precession vortex flow meter can be widely used in petroleum, chemical industry, electric power, metallurgy, urban gas supply and etc.

It is a commonly used product for gas transmission and distribution measurement and trade measurement in oil fields and cities at present.

Working Principle

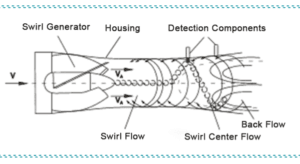

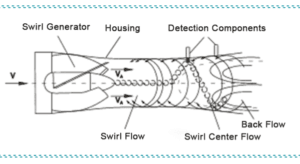

A set of helical guide vanes are installed on the inlet side, which force the fluid to produce violent vortex flow when it enters the flow meter.

When the fluid enters the diffuser section, the vortex flow is affected by the return flow and begins to rotate a second time, forming a gyroscopic vortex oscillation phenomenon. This oscillation frequency is proportional to the flow size and is not affected by the physical properties and density of the fluid. The detection element can measure the secondary rotational oscillation frequency of the fluid to obtain a good linearity in a wide flow range. The signal is amplified, filtered, and shaped by the pre-amplifier and converted into a pulse signal proportional to the flow velocity.

When the fluid enters the diffuser section, the vortex flow is affected by the return flow and begins to rotate a second time, forming a gyroscopic vortex oscillation phenomenon. This oscillation frequency is proportional to the flow size and is not affected by the physical properties and density of the fluid. The detection element can measure the secondary rotational oscillation frequency of the fluid to obtain a good linearity in a wide flow range. The signal is amplified, filtered, and shaped by the pre-amplifier and converted into a pulse signal proportional to the flow velocity.

And then, it is sent to the microprocessor along with temperature and pressure detection signals for accumulation processing and displayed on the LCD as the measurement results (instantaneous flow, accumulated flow, and temperature and pressure data).

Features

- On-site display of temperature, pressure, instantaneous flow and cumulative flow;

- Adopt 16-bit computer chip, with high integration, small size, good performance and strong function of the whole machine;

- Double detection technology can effectively improve the detection signal strength and suppress the interference caused by pipeline vibration;

- Adopt domestic intelligent anti-seismic technology to effectively suppress the interference signals caused by vibration and pressure fluctuation;

- EEPROM technology is adopted, which is convenient for parameter setting and can be stored for a long time, and historical data can be stored for up to one year;

- Chinese character dot matrix display screen is adopted, which has many display digits, intuitive and convenient reading, and can directly display the volume flow in working state, volume flow and total amount in standard state, and parameters such as medium pressure and temperature;

- The flow meter integrates a flow probe, a microprocessor, a pressure sensor and a temperature sensor, and adopts a built-in combination to make the structure more compact. It can directly measure the flow, pressure and temperature of fluid, and automatically track and compensate and correct the compression factor in real time;

- The converter can output frequency pulses and 4 ~ 20 mA analog signals, and has RS-485 interface, which can be directly connected with a microcomputer, and the transmission distance can reach 1.2km;;

- Multi-physical parameter alarm output, one of which can be selected by the user;

- The meter head can rotate at will at 180 degrees, making it easy to install and use;

- With the FM data collector of our company, remote data transmission can be carried out through the Internet or telephone network;

- Pressure and temperature signals are input by sensors, which are highly interchangeable;

Low power consumption of the whole machine, which can be powered by internal battery or external power supply.

When the fluid enters the diffuser section, the vortex flow is affected by the return flow and begins to rotate a second time, forming a gyroscopic vortex oscillation phenomenon. This oscillation frequency is proportional to the flow size and is not affected by the physical properties and density of the fluid. The detection element can measure the secondary rotational oscillation frequency of the fluid to obtain a good linearity in a wide flow range. The signal is amplified, filtered, and shaped by the pre-amplifier and converted into a pulse signal proportional to the flow velocity.

When the fluid enters the diffuser section, the vortex flow is affected by the return flow and begins to rotate a second time, forming a gyroscopic vortex oscillation phenomenon. This oscillation frequency is proportional to the flow size and is not affected by the physical properties and density of the fluid. The detection element can measure the secondary rotational oscillation frequency of the fluid to obtain a good linearity in a wide flow range. The signal is amplified, filtered, and shaped by the pre-amplifier and converted into a pulse signal proportional to the flow velocity.