Description

Gas Roots (Rotary) Flow Meter is an accurate instrument based on the positive displacement measurement principle for gas flow measurement.

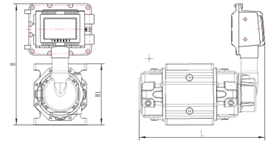

Rotary Flow meter consists of two parts, waist wheel flow sensor and display instrument, it has many advantages, such as high accuracy, wide range, small size, light weight, easy installation and maintenance, reliable use and durable service life and etc.

It commonly used to measure natural gas, coal gas, inert gas, air and other gas flow measurement. It is an ideal flow metering device for domestic and foreign urban gas, oilfield chemical, scientific research and other departments.

Working Principle

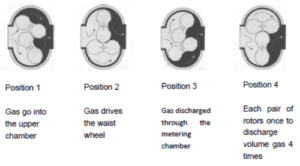

The intelligent Gas Roots Flow Meter is mainly composed of a shell, a conjugate rotor and an intelligent flow integrator. A pair of conjugate rotors installed in the measuring chamber maintain the correct relative position of the rotors through the precision machining adjusting gear under the action of the inlet and outlet pressure difference of the circulating gas (P in > P out). The optimum working clearance is maintained between the rotor, between the rotor and the shell, between the rotor and the wall panel, and continuous non-contact sealing is achieved. For each rotation of the rotor, four times the effective volume of the measuring chamber is output.

Its measurement process and working principle are shown in Figure 2 (only a quarter cycle is shown in the figure).

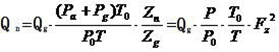

The intelligent flow integrator consists of temperature and pressure detection, flow sensor and microprocessor unit. The microprocessor in the intelligent flow integrator compensates the temperature and pressure according to the gas equation and corrects the compression factor as follows:

············· (1)

············· (1)

In the formula:

Qn: volume flow under standard condition (m3/h);

Qg: volume flow under working condition (m3/h);

Pg: Gauge pressure (kPa) at the pressure detection point of the flow meter;

Pa: local atmospheric pressure (kPa);

Tg: absolute temperature of the medium (273.15+t) (K);

t: Temperature of the measured medium (℃);

Zn: compression coefficient under standard state;

Zg: compression coefficient under working condition;

n: absolute temperature (273.15+20) under standard condition (K);

Pn: Standard atmospheric pressure (101.325kPa).

Note: Natural gas Zn/Zg = Fz2, Fz is called the super compression factor, according to the China National Petroleum Corporation standard SY/T6143-1996 formula to calculate.