When measuring the flow rate of compressed air, there are many types of flow meters to choose from, each based on a unique working principle, and has its own advantages and disadvantages and application scenarios. The following is a detailed analysis of several common compressed air flow meters:

Vortex flow meter

Working principle: Vortex flow meters measure flow through the vortex formed by the fluid behind an obstacle. The frequency of the vortex is proportional to the flow rate, enabling accurate measurement of the flow rate.

Advantages:

- High precision, suitable for the accurate measurement of compressed air flow.

- Real-time monitoring, easy to detect traffic changes in time.

- It has a wide range of applications and is a commonly used instrument for measuring the flow of compressed air.

Weaknesses:

It is sensitive to impurities and pulsations in the fluid, which may affect the measurement accuracy.

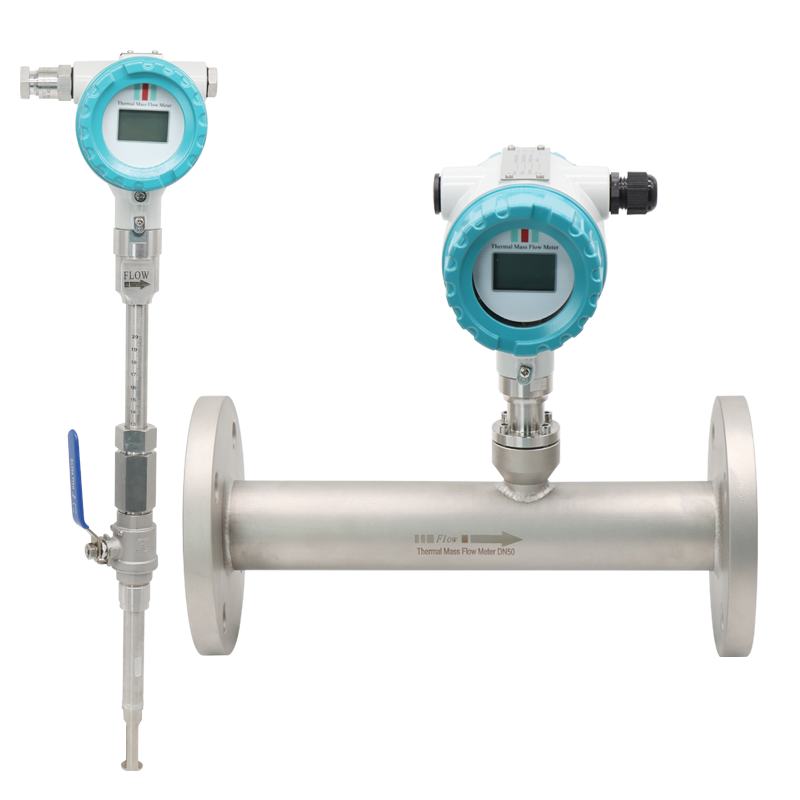

Thermal gas mass flow meter (main thrust for measuring compressed air without moisture)

Working principle: The thermal flow meter uses the principle of heat conduction to measure gas flow through heating elements and temperature sensors. As the gas flows, it carries away heat, resulting in a change in temperature, thus calculating the flow rate.

Advantages:

- It is not sensitive to changes in gas composition and humidity, and the measurement is stable.

- Fast response speed, real-time monitoring of traffic changes.

Weaknesses:

If the air contains moisture, it cannot be measured.

Differential flow meter

Working principle: Differential pressure flow meters calculate the flow rate by measuring the difference in pressure produced by the fluid as it flows through the pipe. Common are venturi tube and orifice flow meters.

Advantages:

- Simple structure, easy to install and maintain.

- The cost is relatively low and suitable for projects with limited budgets.

Weaknesses:

The measurement accuracy is greatly affected by the state of the fluid (e.g., Reynolds number, fluid viscosity, etc.) and may require additional calibration.

Precession vortex flow meter

Working principle: The precession vortex flow meter measures flow through the vortex formed by the fluid behind the vortex generator. The frequency of the vortex is proportional to the flow rate, so that the flow rate can be measured.

Advantages:

- Suitable for low flow rate, small diameter measurement.

- Simple structure and easy maintenance.

Weaknesses:

- It is sensitive to impurities and pulsations in the fluid, which may affect the measurement accuracy.

- The scope of application is relatively limited.

- Comprehensive comparison and selection

When choosing a compressed air flow meter, consider the following factors:

- Measurement accuracy: Select the appropriate accuracy level according to the measurement requirements.

- Fluid characteristics: Consider the composition of the gas, humidity, pressure, temperature and other factors, choose the appropriate flow meter.

- Installation conditions: The installation position of the flow meter and the diameter of the pipe will affect its performance, and it needs to be planned in advance.

- Maintenance requirements: Some flow meters require regular calibration and maintenance, and the convenience of maintenance should be considered when selecting them.

- Cost budget: Select the right flow meter type according to the budget.

In summary, the choice of compressed air flow meter should consider the specific application scenario, measurement accuracy requirements, fluid characteristics, installation conditions, maintenance needs and cost budget. In practical applications, the characteristics and advantages of a variety of flow meters can be combined to choose the most suitable flow meter type to meet the measurement needs.

If you want to know more about the flow meter or flow meter selection, please consult the Aister flow meter manufacturer email: sales@aistermeter.com for help.